Broiler Production Stages, Guidelines, and Best Practices

Broiler farming is one of the most popular and profitable sectors of the poultry industry. It involves raising chickens for meat production, ensuring they grow quickly and efficiently.

Whether you're new to poultry farming or looking to optimize your existing operation, understanding the basics of broiler production is key to success.

The goal of this article is to provide you with clear, practical guidelines and best practices that will help you run an efficient and profitable broiler farm.

What is broiler production?

Broiler production is the process of raising chickens specifically for meat, often on a large scale, to meet consumer and market demands.

Broilers are a type of chicken bred for rapid growth, efficient feed conversion, and high meat yield. The goal of broiler farming is to raise these birds from day-old chicks to market weight in a short period, typically between 5 to 7 weeks, depending on the breed and management practices used.

This process involves several key stages:

- Selecting the right breed

- Providing appropriate housing

- Managing feed and nutrition

- Ensuring strict health and biosecurity measures.

Each stage plays a critical role in the success of broiler production, and farmers need to implement best practices at every step to ensure optimal growth rates and meat quality.

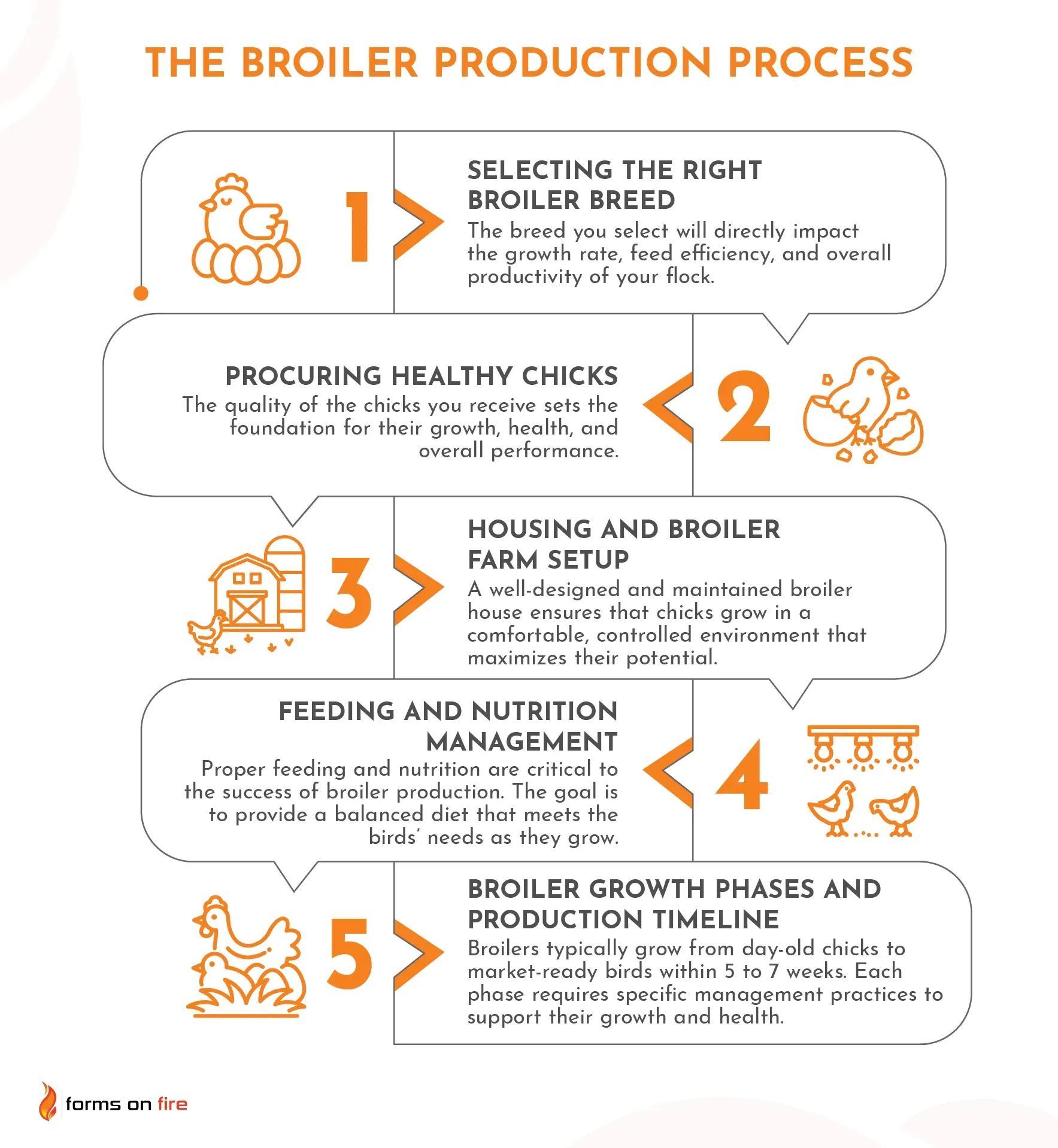

The broiler production process: From chick to market

Understanding the entire lifecycle of broiler production, from the moment chicks arrive on the farm to their final market preparation, is essential for both new and experienced farmers.

Each of the following stages is designed to optimize the growth and health of the birds to achieve market weight efficiently.

1. Selecting the right broiler breed

The breed you select will directly impact the growth rate, feed efficiency, and overall productivity of your flock. While there are several breeds available, the most popular ones for commercial broiler production include:

- Cornish Cross: Known for their rapid growth and large breast meat yield, Cornish Cross is the most widely used breed in commercial broiler farming. These birds are typically ready for market in 6 to 8 weeks.

- Cobb 500: This breed is favored for its excellent feed conversion ratio (FCR) and uniform growth. Cobb 500 broilers are efficient meat producers and can reach market in 6 to 7 weeks, making them a common choice for large-scale operations.

- Ross 308: Similar to the Cobb 500, Ross 308 broilers are known for their efficient growth, adaptability, and consistent meat quality. They are popular among farmers who prioritize uniformity and high meat yield.

When selecting a breed, farmers need to pay special attention to growth rate, Feed Conversion Ratio (breeds with a lower FCR will consume less feed while gaining more weight), and demands of their target market (some customers may prefer birds with higher breast meat yield, while others might prefer smaller, leaner birds).

2. Procuring healthy chicks

The quality of the chicks you receive sets the foundation for their growth, health, and overall performance.

To ensure you start with the best, follow these guidelines:

- Select reputable hatcheries: Look for hatcheries that have a proven track record for delivering high-quality, vaccinated chicks. It's also helpful to choose hatcheries that provide information on the genetic background of the chicks, so you know what growth and performance characteristics to expect.

- Inspect chicks upon arrival: When your chicks arrive, inspect them closely to ensure they are healthy and active. Healthy chicks should be alert, have clear eyes, and exhibit lively behavior. Avoid chicks that appear lethargic, have deformed legs, or show signs of respiratory issues.

- Proper transport and handling: The way chicks are transported from the hatchery to the farm can impact their initial health and performance. Ensure that transport conditions are controlled — chicks should be kept at an appropriate temperature and should have enough space to avoid overcrowding and stress.

This can be time-consuming, but it also lays the groundwork for a productive and profitable flock.

3. Housing and broiler farm setup

A well-designed and maintained broiler house ensures that chicks grow in a comfortable, controlled environment that maximizes their potential.

Here’s what to consider when setting up your broiler farm:

- Broiler house design: The house should provide enough space for the birds to move comfortably, with sufficient floor area to prevent overcrowding. Plan for about 0.5 to 0.7 square feet per bird. Ultimately, the layout and size of your broiler house depend on the number of birds you plan to raise.

- Ventilation: Proper ventilation is crucial to maintain air quality and control humidity within the broiler house. Install fans or vents to circulate fresh air, remove excess moisture, and manage ammonia levels from the litter.

- Lighting: Install adjustable lighting systems that provide continuous light in the early stages to encourage feeding and drinking.

- Temperature control: Maintaining the right temperature is essential, especially during the brooding stage. Consider installing thermostats and heating systems to adjust temperatures based on the flock’s needs.

- Litter management: Use absorbent materials like wood shavings or straw for litter, spreading it evenly across the floor to a depth of 2-3 inches. Regularly monitor and change the litter to maintain cleanliness, prevent ammonia buildup, and minimize odor.

Setting up the right environmental conditions (temperature, lighting, humidity, etc.) is an essential part of broiler farm management. We will discuss actual numbers later in the article.

4. Feeding and nutrition management

Proper feeding and nutrition are critical to the success of broiler production. The goal is to provide a balanced diet that meets the birds’ needs as they grow.

Broilers go through three main feeding stages — starter, grower, and finisher. Each stage has specific nutritional requirements to support the bird’s growth. In general, broilers require a balanced mix of nutrients, including proteins, carbohydrates, fats, vitamins, and minerals.

While you can mix your own feed, most farmers will rely on well-formulated, commercial feed that meets the nutritional requirements for each stage.

Before we move on, let’s also mention that providing clean, fresh water at all times is just as important as the feed. These days, you can use automated watering systems that maintain consistent water flow and cleanliness.

5. Broiler growth phases and production timeline

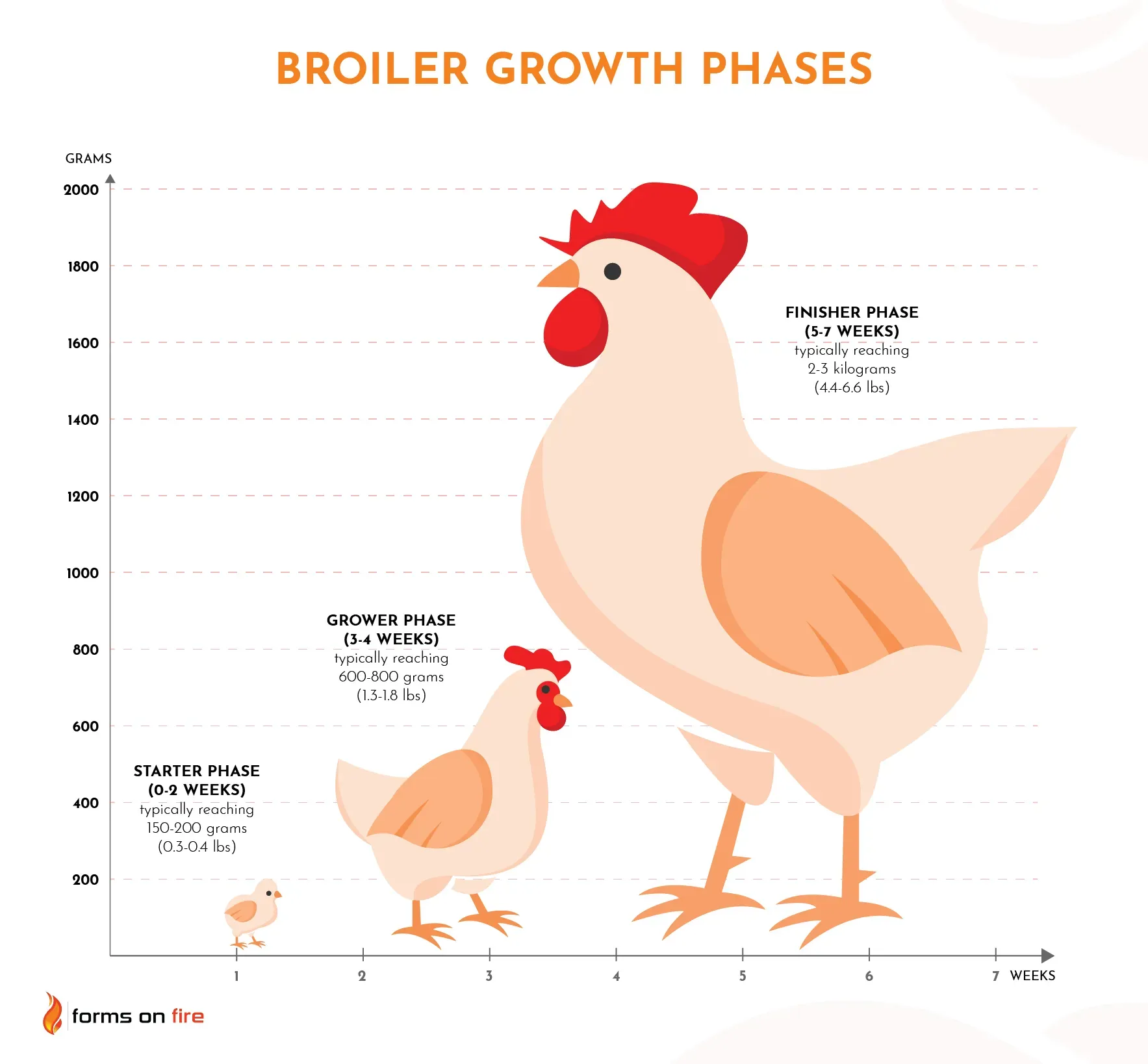

Broilers typically grow from day-old chicks to market-ready birds within 5 to 7 weeks. Each phase requires specific management practices to support their growth and health:

- Starter phase (0-2 weeks): During the first two weeks, chicks experience rapid growth and development. By the end of the starter phase, chicks should have doubled or tripled their initial weight, typically reaching around 150-200 grams (0.3-0.4 lbs).

- Grower phase (3-4 weeks): This phase focuses on continued growth and muscle development. Birds will begin to grow rapidly and gain significant body mass. Broilers should reach approximately 600-800 grams (1.3-1.8 lbs) by the end of this phase.

- Finisher phase (5-7 weeks): In the final stage, broilers focus on weight gain and fat deposition. The goal is to maximize growth while maintaining feed conversion rates. By the end of the finisher phase, broilers should weigh 2-3 kilograms (4.4-6.6 lbs) depending on breed and management).

Each stage requires different management and conditions. For example, in the first stage, chicks benefit from higher temperatures and feed with more protein content than later in their development.

Each farmer should get familiar with different feed, temperature, and lighting requirements for their breeds before getting started.

Key considerations and best practices for successful broiler production

Achieving consistent success in broiler production goes beyond simply following a growth schedule — it requires attention to several critical factors that influence the overall health, growth rate, and productivity of your flock.

Strict biosecurity measures

Proper biosecurity measures help prevent the spread of diseases that can severely impact flock health. Here’s what you can do:

- Restrict access: Limit access to your broiler farm to essential personnel. Anyone entering the facility should wear protective clothing, disinfect footwear, and wash hands thoroughly before and after entry.

- Disinfect equipment and facilities regularly: Disinfect feeders, drinkers, and other equipment regularly to minimize the risk of bacteria or virus buildup. Ensure that vehicles and tools used within the farm are also cleaned and disinfected before and/or after use.

- Isolate sick birds: Establish a designated quarantine area for sick birds and monitor them closely.

- Vaccination schedules and monitoring: Follow a proper vaccination schedule as recommended by poultry veterinarians or industry standards. Keep detailed records of vaccinations for compliance.

- Control pests and rodents: Rodents and other pests can carry diseases that affect broilers. Implement rodent control measures, such as traps and bait stations, around the perimeter of the broiler house. Keep the environment clean and dispose of feed waste properly to minimize attractants.

Implementing these practices will help you prevent disease outbreaks and facilitate more sustainable broiler production.

Managing broiler health

First, it’s important to recognize what a healthy bird looks like compared to a sick one.

Healthy broilers are active, have clear eyes, smooth feathers, and show a keen interest in feeding and drinking. Sick birds, on the other hand, may appear lethargic, have ruffled feathers, exhibit labored breathing, or show signs of diarrhea or reduced appetite.

There isn’t anything better at catching early signs of disease than regular health checks. Schedule periodic inspections to assess bird health and environmental conditions. Keeping detailed health records helps track the flock’s history and spot trends.

Sooner or later, you’ll have to deal with sick chicks. To make things easier, establish a protocol for dealing with illnesses. This should include isolating affected birds, administering medication, and consulting a veterinarian to determine the best course of action. Try to keep a record of any treatments or interventions, including doses and dates, to monitor recovery and improve future response strategies.

Environmental management guidelines

The goal of environmental management is to reduce stress and health issues, ensuring that your broilers thrive. Focus on the following areas:

- Temperature control: In the brooding phase, keep the temperature at 32-35°C (90-95°F) to ensure chicks stay warm. Gradually reduce the temperature by 2-3°C per week as the birds grow, aiming for around 21-24°C (70-75°F) in the final stages.

- Humidity management: Maintaining appropriate humidity levels (typically 50-70%) helps prevent respiratory issues and maintains litter quality. Use ventilation systems and fans to regulate humidity levels and keep the air fresh.

- Lighting programs: In the early stages, provide continuous light to encourage feeding and drinking. As birds mature, adjust to 16 hours of light/8 hours of darkness schedule to balance activity and rest.

Chicks are very sensitive to environmental conditions, so it’s important to get this right, especially if you want to scale your operations.

Lighting programs for growth and performance

The intensity of light affects broilers’ activity levels, influencing how often they feed and move.

In the early stages, brighter light (typically 20-40 lux) encourages chicks to be active, ensuring they find feed and water. As they grow, light intensity is gradually reduced to 5-10 lux to promote calm behavior, reducing stress and minimizing aggressive actions like pecking.

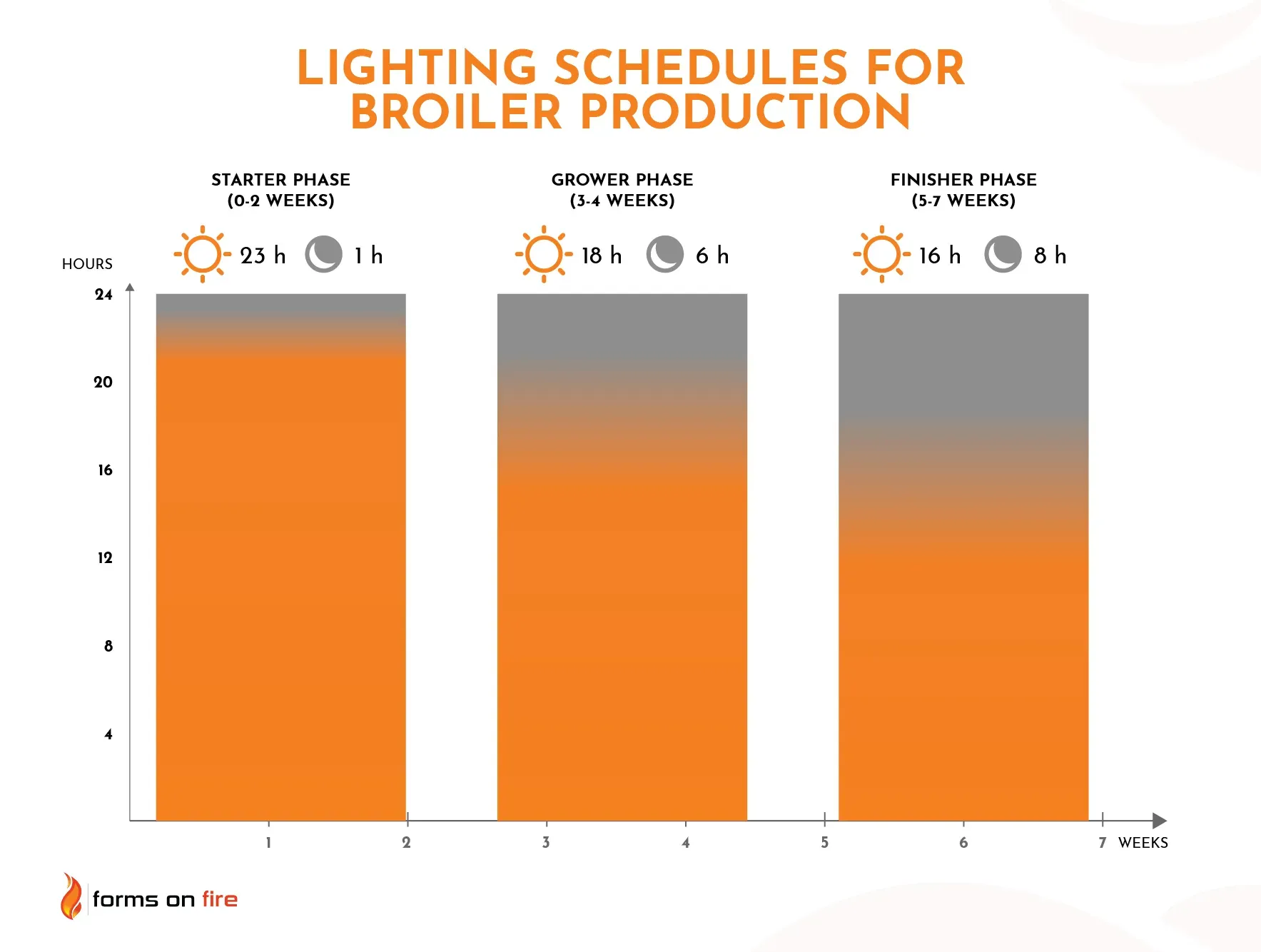

Lighting schedules are essential for regulating the daily activity patterns of broilers:

- Starter phase (0-2 weeks): Provide 23-24 hours of light per day to ensure chicks are active and consuming feed frequently.

- Grower phase (3-4 weeks): Transition to a lighting schedule of 18-20 hours of light and 4-6 hours of darkness. This adjustment helps broilers maintain growth momentum while also allowing them time to rest and recover, which is important for muscle development.

- Finisher phase (5-7 weeks): Reduce the light duration to 16 hours of light and 8 hours of darkness. This schedule helps maintain a balance between feeding activity and rest, supporting continued weight gain while reducing stress and aggression as birds reach market weight.

In general, try to maintain a consistent lighting schedule and avoid sudden changes that could stress the birds. Consider automated lighting systems to precisely control light duration and intensity based on the growth stage.

Waste management best practices

Proper disposal and management of litter, manure, and other waste products help minimize disease risks, reduce odors, and promote sustainability.

Here are some waste management tips to employ:

- Efficient disposal of litter and manure: Regularly check litter conditions and replace or add fresh bedding as needed to maintain cleanliness and absorb moisture. Manure mixed with litter should be safely removed at the end of each production cycle.

- Reducing odor and flies: Use absorbent litter material and maintain appropriate stocking densities to keep litter dry and minimize odor. Install fly traps and regularly inspect the farm for fly breeding sites. Keep manure storage areas covered to prevent flies from accessing and breeding in the waste.

- Composting and recycling manure for fertilizers: Composting litter and manure reduces odor, eliminates pathogens, and creates nutrient-rich organic material that can be used as fertilizer. Manure can also be a valuable resource for fertilizing crops, either on your farm or as a product sold to other farmers.

It’s not glamorous, but proper waste management can have a big positive impact on farm efficiency and sustainability.

Efficient feed conversion

FCR measures how efficiently broilers convert feed into body weight. Optimizing this ratio is essential for maximizing growth while minimizing feed costs.

As we mentioned earlier, farmers will want to provide balanced nutrition at different growth stages, use high-quality feed ingredients, and distribute feed evenly and frequently to minimize competition and wastage.

Investing in high-quality feed might seem costly initially, but it improves FCR and reduces the overall amount of feed required to achieve market weight. This can lead to significant cost savings and higher profits in the long run.

Calculating and tracking FCR can be time-consuming. You’ll want to implement digital monitoring tools or broiler farm management software to track feed usage and growth trends in real time.

If you notice that the FCR is higher than expected, investigate potential causes such as feed quality, environmental conditions (e.g., temperature fluctuations), or health issues. Adjust feeding strategies, environmental management, or veterinary care based on these findings to optimize feed conversion.

Streamline poultry production with Forms On Fire

Efficient broiler production requires meticulous record-keeping, monitoring, and management of various processes. Forms On Fire helps farmers simplify and optimize broiler production by digitizing select tasks and processes.

Farmers across North America use our platform to manage everything from hatcheries and feed mills to farm inventory, record-keeping, and even food traceability.

How Forms On Fire can help:

- Simplified data collection: Track essential information such as feed consumption, bird weight, vaccination schedules, and environmental conditions using mobile devices. Record data in real time, ensuring accuracy and consistency while reducing paperwork.

- Customizable forms and reports: Build and tailor forms to suit your specific farm needs, whether it's monitoring daily feed intake or conducting health inspections. Automated reporting features compile the data, allowing you to quickly analyze and make informed decisions that optimize productivity and minimize risks.

- Remote monitoring and access: Stay connected to your broiler operation from anywhere by accessing the app on your phone. Your frontline workers can use our platform’s offline capability to collect and record data even when they have no internet access.

- Improved biosecurity and compliance: Track biosecurity protocols and chick health records efficiently. Digital logs and reports can be used to demonstrate compliance during inspections or audits, offering peace of mind.

By using Forms On Fire, broiler farmers can streamline production processes, enhance productivity, and make data-driven decisions that lead to better growth rates, reduced losses, and increased profitability.

In such a competitive market, having the right tools in place can make a world of difference. See what Forms On Fire can do for you by requesting a demo or starting a free trial.