How to Start With Business Process Digitalization

Digitalizing your business processes can lead to big wins: faster workflows, fewer errors, better data, and a more efficient team. It can also help you cut costs and deliver better service.

But, as it often is, big wins require overcoming real challenges.

You’re dealing with legacy systems, resistance to change, and the sheer number of processes that could be improved. On top of that, it’s not always clear where to begin or which tools to use.

That’s exactly what this article is here to help with. We’ll walk through what business process digitalization actually means, explain different ways to approach it, and give a step-by-step guide to help you get going — even if you’re not a tech expert.

What it means to digitalize a business process

Digitalizing a business process means using technology to replace manual steps with digital or automated workflows. It’s not just about digitizing paper documents or sending group WhatApps messages instead of organizing in-person meetings. It’s about rethinking how work gets done using digital tools to make processes faster, more accurate, and easier to scale.

At its core, process digitalization is about working smarter — not just throwing tech at a problem, but using the right tools to create better workflows.

Process digitization vs process digitalization

These two terms sound almost the same, but there’s a subtle (and important) difference:

- Process digitization is about converting analog info into digital form. Think: scanning paper forms into PDFs or replacing physical checklists with a spreadsheet.

- Process digitalization goes a step further. It involves rethinking and redesigning a process using digital tools. For example, instead of filling out a paper inspection form, a field worker uses a mobile app that guides them through the process, uploads photos, and instantly sends the report to the office. That’s a whole new (and better) way of doing the task.

So, digitization is a step toward digitalization — but digitalization is where the real transformation happens.

Approaches to business digitalization

There’s no one-size-fits-all way to digitalize a business process. The right approach depends on your goals, your team, and your budget. Here are three common ways organizations tackle it:

- Implement off-the-shelf software: Great for standard processes like payroll, HR, or accounting. These tools are ready to go, are usually cloud-based, and come with built-in best practices. The tradeoff? Very limited customizability.

- Digitize workflows using a no-code platform: No-code tools like Forms On Fire let non-developers build custom apps and forms — great for teams that want to move fast without depending on IT. You can create digital inspection checklists, field reports, approval flows, etc., using simple drag-and-drop tools.

- Develop a system from scratch: This is the most flexible (and the most resource-intensive) option. If your process is highly specialized, developing your own software might make sense. Just be ready for significantly higher costs and longer timelines.

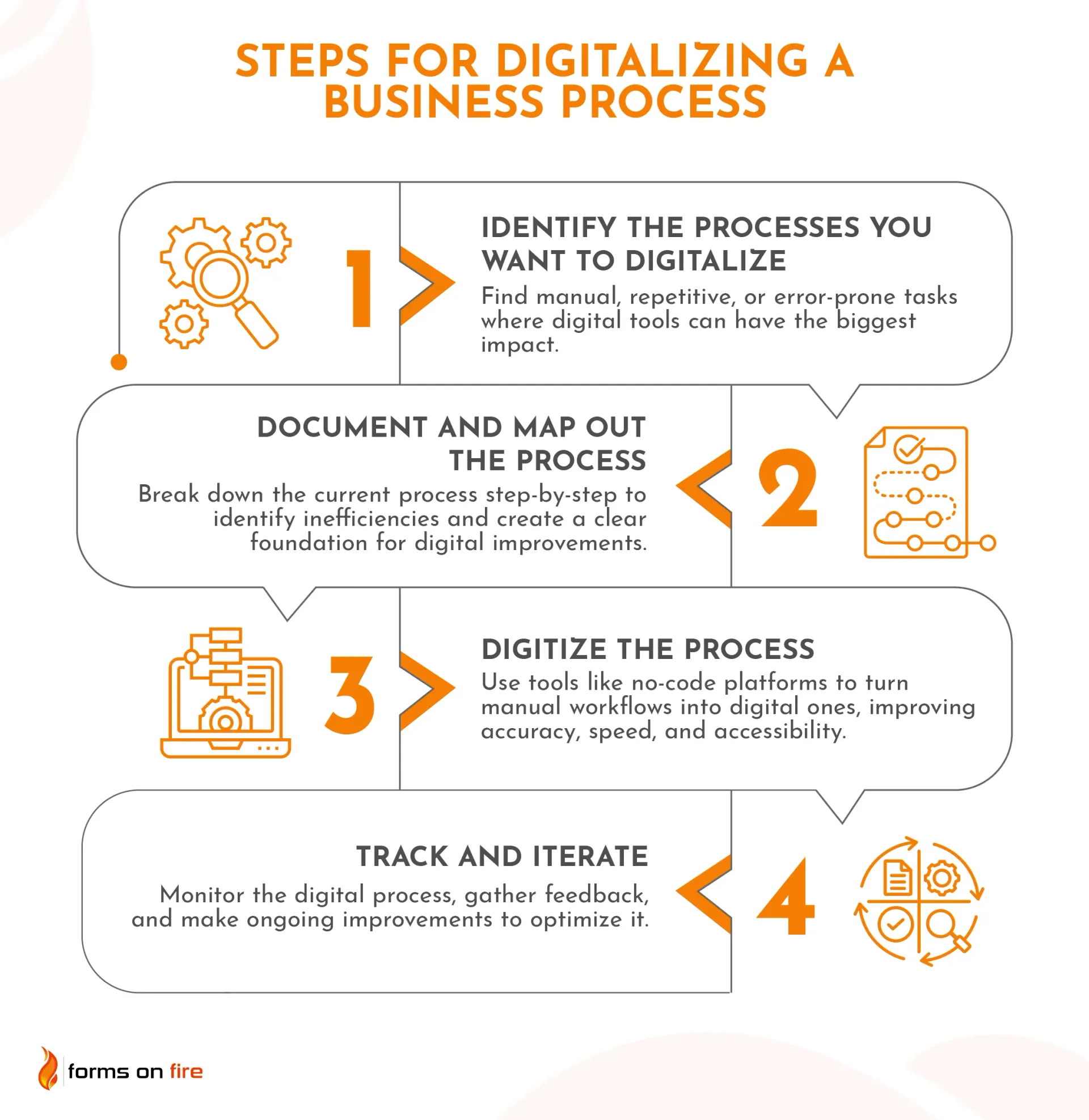

Steps for business process digitalization

Process digitalization sounds more complex than it actually is. Whether you’re in construction, healthcare, transportation, or field services, the approach stays the same: understand the process, choose the right tools, implement, and polish.

That said, industries with mobile or field-based teams often have the most to gain. Think about teams doing inspections, maintenance, deliveries, or home visits. These are often full of paper-heavy, error-prone, and hard-to-track processes — making them perfect candidates for digitalization.

In the next sections, we’ll walk through the key steps, from identifying the right processes to tracking and optimizing your new digital workflows.

1) Identify the processes you want to digitalize

The first step is figuring out what to digitalize. As with business process optimization, we recommend focusing on the areas where digital tools can make the biggest impact.

Here are some common characteristics of processes that are prime for digitization and digitalization:

- Manual and repetitive: Think data entry, paperwork, or sending the same email over and over. Example: daily safety checklists on paper.

- Error-prone: If people often forget steps or make mistakes, that’s a red flag. Example: manual inventory tracking that leads to stockouts or overordering.

- Time-consuming: Long approval chains or handoffs slow everything down. Example: waiting for a signed paper form to be physically handed to someone else.

- Hard to track: If you can't easily see the status of a process, it's tough to manage. Example: tracking maintenance requests that come in via phone calls or text messages.

- Field-based or mobile: Processes that happen outside the office are often disconnected from your systems. Example: site inspections that get documented in a notebook, then typed up later.

If you’ve got a long list of processes that need a revamp, prioritize based on:

- Impact — Which ones will save the most time or reduce the most errors?

- Pain level — Which processes are the most frustrating for your team?

- Feasibility — What can you realistically tackle with your current resources?

Start small. For instance, you can use mobile forms software to digitialize one or two high-impact processes and go from there. Quick wins build momentum.

2) Document and map out the process

Once you’ve picked a process to digitalize, you need to understand exactly how it works today. That means documenting it step-by-step — what happens, who’s involved, what tools are used, and where the pain points are.

Here’s how you can gather the info you need:

- Talk to the people who do the work: Interviews and shadowing are super helpful. Ask them to walk you through a typical day.

- Review existing documentation: Look at forms, reports, emails, or spreadsheets related to the process.

- Observe the process in action: Watch how it actually unfolds. You might notice steps or issues that no one mentions.

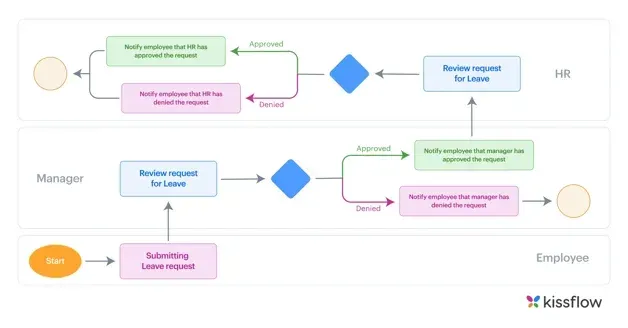

If it is a complex process, it doesn’t hurt to

map it out. Start with the first trigger (e.g. an employee submits a

time off request form) and follow it to the end. Tools like Lucidchart, Miro, or even a good old whiteboard can work.

This helps you:

- Spot unnecessary steps or delays

- Identify areas that could be automated or simplified

- Create a baseline to compare the digital version against.

You don’t need a perfect map — just something that clearly shows how things work today. It'll guide your digitalization efforts and help you explain the changes to your team later.

3) Digitize the process

Now it’s time to actually make the shift from manual to digital. Use one of the approaches we mentioned earlier — off-the-shelf software, a no-code platform, or a custom build — depending on your needs.

Let’s look at two practical before-and-after examples using a no-code platform, which is often the fastest and most flexible option for digitalizing specific internal processes.

🏗️ Construction: Site inspections

Before: A site supervisor uses a clipboard to complete a daily inspection checklist. At the end of the day, they take photos on their phone, then go back to the office to type everything into a report and email it to the safety manager.

After: The supervisor uses a mobile app built on a no-code platform. They open the app on their mobile device, which walks them through the checklist, lets them attach photos, and add notes with voice-to-text. When they click “Submit”, the app automatically sends a completed report to the right people. Everything is stored securely and instantly accessible from the office.

🚚 Transportation & logistics: Vehicle audits

Before: Drivers fill out vehicle inspection forms on paper each morning. Forms are handed in at the end of the shift. Someone from the admin team manually enters the data into a spreadsheet. The management keeps their fingers crossed and hopes all of the entered data is accurate.

After: Drivers complete inspections via a mobile app. It captures signatures, photos of any issues, and GPS location. The data flows into a central dashboard in real time, where the fleet manager can spot problems instantly and schedule maintenance faster.

After digitalizing a process, make sure to document the new workflow. Update your operating procedures and go through it with your team. Train the new hires using the updated workflow from day one.

4) Track and iterate

Just because a process is digital doesn’t mean it’s perfect. In fact, new workflows often reveal issues you couldn’t see before — like unnecessary steps or new bottlenecks caused by automation.

That’s why tracking and iteration are important.

After rolling out a digital process, keep an eye on it. Use built-in analytics or ask your team what’s working and what’s not.

Here are a few things to watch for:

- Bottlenecks: Maybe an approval step is still too slow — or it wasn’t even needed in the first place.

- User drop-off: Are people skipping steps or avoiding the system altogether? That might mean it’s too clunky or needs more training.

- New manual workarounds: If people are creating spreadsheets or doing tasks outside the system, your digital workflow might need tweaking.

And that’s totally normal.

The beauty of digital processes — especially when using digital forms — is that you can make changes quickly. Tweak the workflow, remove extra steps, or automate more tasks as you go.

Simplify the digitization of business processes with Forms On Fire

Forms On Fire is a no-code mobile platform that lets teams build custom forms, automate workflows, collect data in the field, and sync everything in real time. You don’t need to be a developer — just find a template in our database, edit it using drag and drop, and deploy it for your whole team to use.

We have a bunch of awesome, built-in features that help you fully customize your processes, especially if you manage frontline teams or have a mobile workforce.

Case study: Alistair Group streamlines vehicle inspections

Logistics company Alistair Group replaced their paper-based vehicle inspections with a mobile solution built on Forms On Fire. Drivers used digital forms in Swahili (auto-translated to English for management), allowing accurate, real-time reporting — even offline. NFC tags improved equipment tracking, and automated alerts helped quickly address safety issues. The result? Faster inspections, better compliance, and huge time savings on data entry and reporting.

We can cite dozens of similar success stories. There’s no reason why you can’t become one of them.

Start your free trial or schedule a demo — and let our team show you how Forms On Fire can simplify your digitalization journey.

FAQ about process digitalization

Do I need to hire developers to digitalize a process?

Not necessarily. No-code platforms like Forms On Fire let you build custom forms and workflows without writing any code. They’re a great option if you want to move fast and keep things in-house.

What if my team isn’t tech-savvy?

That’s okay — many digital tools are designed to be user-friendly. Start small, provide simple training, and explain the why behind the change. Often, once people see how much easier it makes their job, they’re on board.

How long does it take to digitalize a process?

It depends on the complexity of the process and the approach you choose. Some workflows can be digitized in a few days with a no-code tool. Others (like building custom software) might take months. The key is to start small and build momentum.

Will digitalization replace jobs?

Not usually. In most cases, digitalization frees people from repetitive, low-value tasks so they can focus on more important work. Its primary goal is to improve efficiency — not cut headcount.

Is Forms On Fire only for field work?

Not at all. While it’s great for mobile and field-based teams, it can also be used in office environments — for things like onboarding, approvals, audits, and internal reporting.