Confined Space Entry Checklist

Spaces with limited or restricted entry and exit points can not only be hazardous themselves, but they can also contain a hazardous atmosphere. This is why these types of spaces should only be accessed by trained professionals who complete a confined space entry checklist — for their own safety, as well as the safety of others.

Click on the button bellow to start a free trial of Forms On Fire and get instant access to our checklist database that

includes a confined space entry checklist template.

This article answers the following questions:

- What is a Confined Space?

- Why is a Confined Space Entry Checklist Necessary?

- What Does a Confined Space Entry Checklist Look Like?

- What is a Confined Space Entry Report?

- Where Do I Get a Confined Space Entry Checklist?

- Frequently Asked Questions

What is a Confined Space?

Some workplaces have areas that are considered confined spaces because they are not necessarily designed for people to occupy them. However, those spaces may be just large enough for workers to enter and perform certain jobs. A confined space also has limited or restricted means for entry or exit.

Examples include: tanks, vessels, silos, storage bins, hoppers, vaults, pits, manholes, tunnels, equipment housings, ductwork, pipelines, etc.

Why is a Confined Space Entry Checklist Necessary?

A confined space can hide many hazards and is one of the leading causes of occupational fatalities. A checklist assists each person entering the confined space with identifying those hazards and mitigating them prior to entering the space. Going through each question on the checklist familiarizes a person with the potential dangers and helps with properly preparing for a safe entry and exit.

Moreover, the confined space entry checklist creates a paper receipt of the steps the company and the person entering the confined space have taken to ensure the workers’ safety. This receipt can be useful if an injury does occur and legal problems follow. It can be poof that appropriate safety measures were taken.

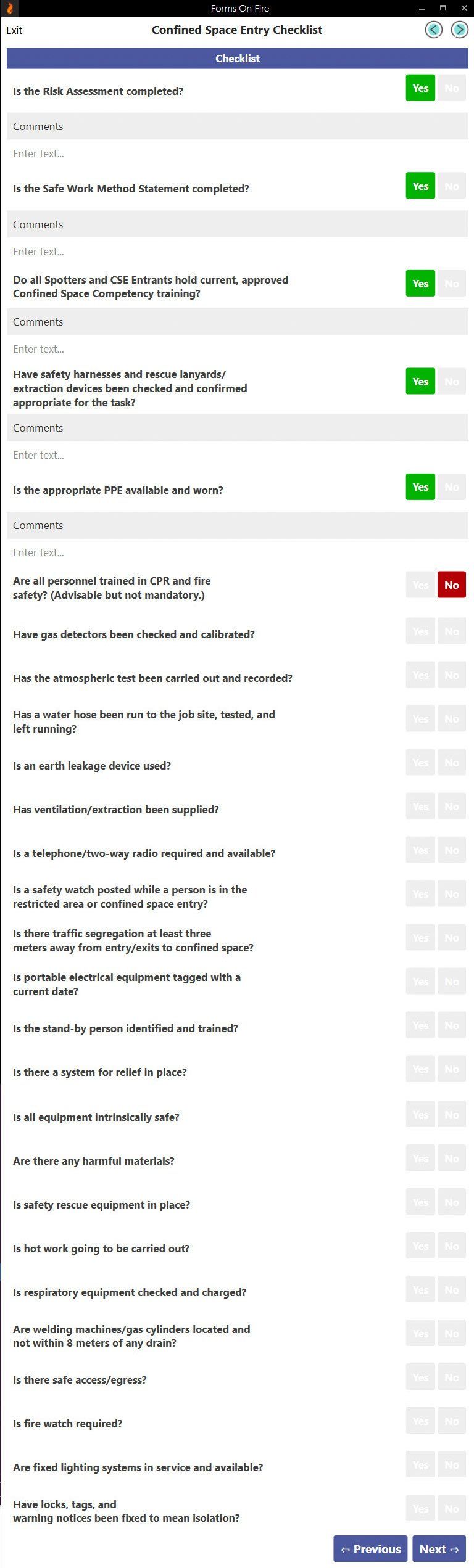

What Does a Confined Space Entry Checklist Look Like?

A confined space entry checklist should include the following questions:

- Is the Risk Assessment completed?

- Is the Safe Work Method Statement completed?

- Do all Spotters and CSE Entrants hold current, approved Confined Space Competency training?

- Have safety harnesses and rescue lanyards/extraction devices been checked and confirmed appropriate for the task?

- Is the appropriate PPE available and worn?

- Are all personnel trained in CPR and fire safety? (Advisable but not mandatory.)

- Have gas detectors been checked and calibrated?

- Has the atmospheric test been carried out and recorded?

- Has a water hose been run to the job site, tested, and left running?

- Is an earth leakage device used?

- Has ventilation/extraction been supplied?

- Is a telephone/two-way radio required and available?

- Is a safety watch posted while a person is in the restricted area or confined space entry?

- Is there traffic segregation at least three meters away from entry/exits to confined space?

- Is portable electrical equipment tagged with a current date?

- Is the stand-by person identified and trained?

- Is there a system for relief in place?

- Is all equipment intrinsically safe?

- Are there any harmful materials?

- Is safety rescue equipment in place?

- Is hot work going to be carried out?

- Is respiratory equipment checked and charged?

- Are welding machines/gas cylinders located and not within 8 meters of any drain?

- Is there safe access/egress?

- Is fire watch required?

- Are fixed lighting systems in service and available?

- Have locks, tags, and warning notices been fixed to mean isolation?

The checklist should also include the following information about the person who performed and approved the inspection:

- Name

- Contact Number

- Signature

- Place

- Date

Of course, these questions are not suitable for every situation. You will need to add or subtract checks based on your use case. Sidenote: You can’t be overcautious.

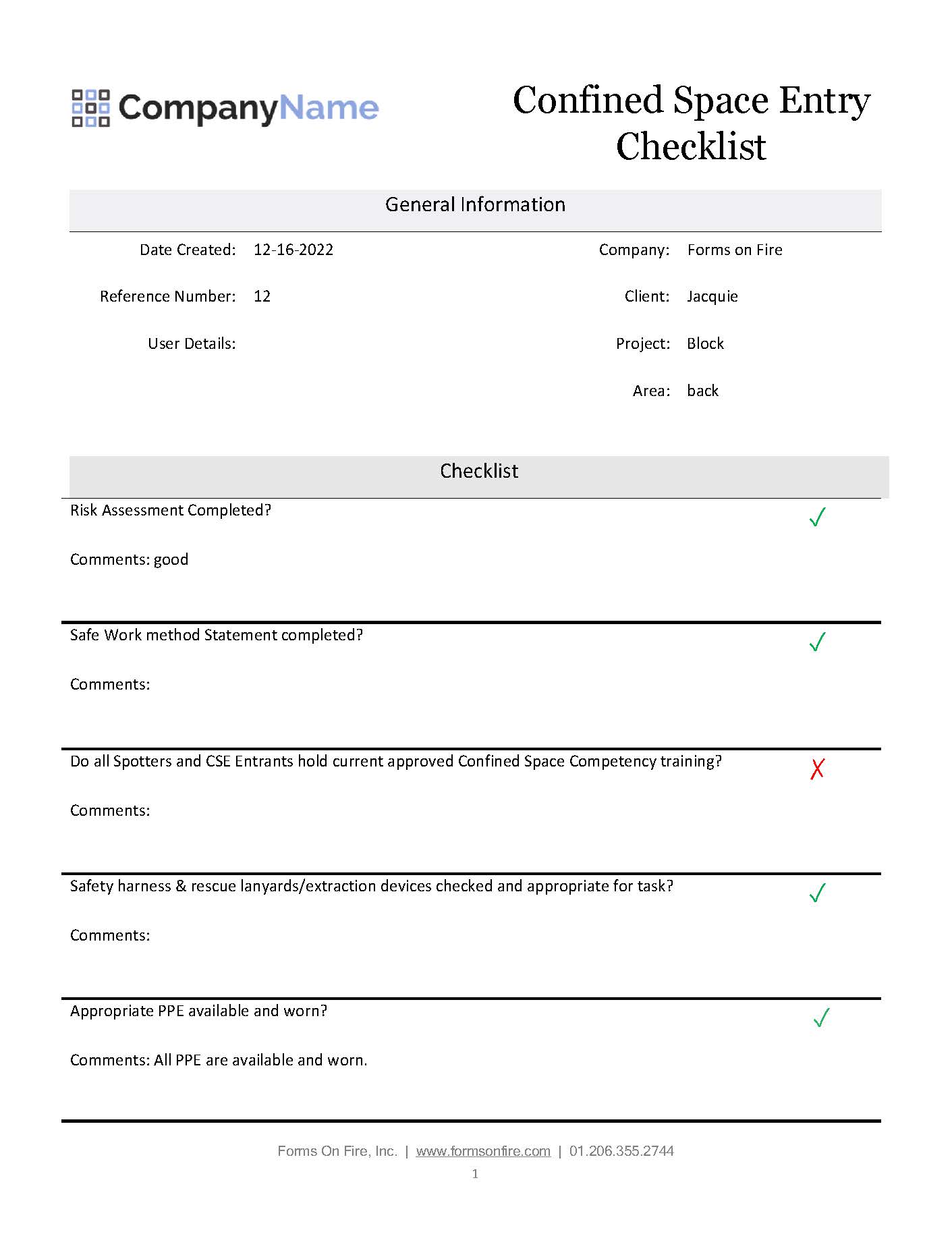

Bellow is a snapshot of a confined space entry checklist built with Forms on Fire.

What is a Confined Space Entry Report?

A confined space entry report is a PDF file of a digitally completed checklist. A person with the appropriate authority can view these checklists as they are completed. A completed checklist serves as proof that various safety precautions were met.

Here is an snapshot of a report based on the checklist we showed above.

Where Do I Get a Confined Space Entry Checklist?

Of course, you can prepare your own confined space entry checklists with your word processing software and a printer. However, to ensure thoroughness, it helps to use an automated inspection tool like Forms On Fire.

Forms On Fire offers hundreds of form templates — including a confined space entry checklist — that you can customize to your exact needs. You can then publish your checklist and distribute it to your team, who can complete and submit completed versions while in the field using a smart device. Additionally, you can generate reports using information from the checklists. The entire automated process removes any need to keep track of hard copies, duplicate data-entry tasks, and manually submit and track information.