How to Mitigate the Most Common Farm Hazards

According to the data from US Labor Statistics and NIOSH, there were 21,020 reported injuries in agricultural production in 2022 that required days away from work. This makes agriculture one of the most dangerous industries to work in.

Farms are major contributors to those statistics. Be it extreme weather, livestock, machinery, chemicals, or confined spaces, there are so many ways things can (and do) go wrong. The good news is that, with the right mindset and safety practices, the majority of farm incidents are easily preventable.

So, let’s see what are the most common hazards on a farm — and how to deal with them.

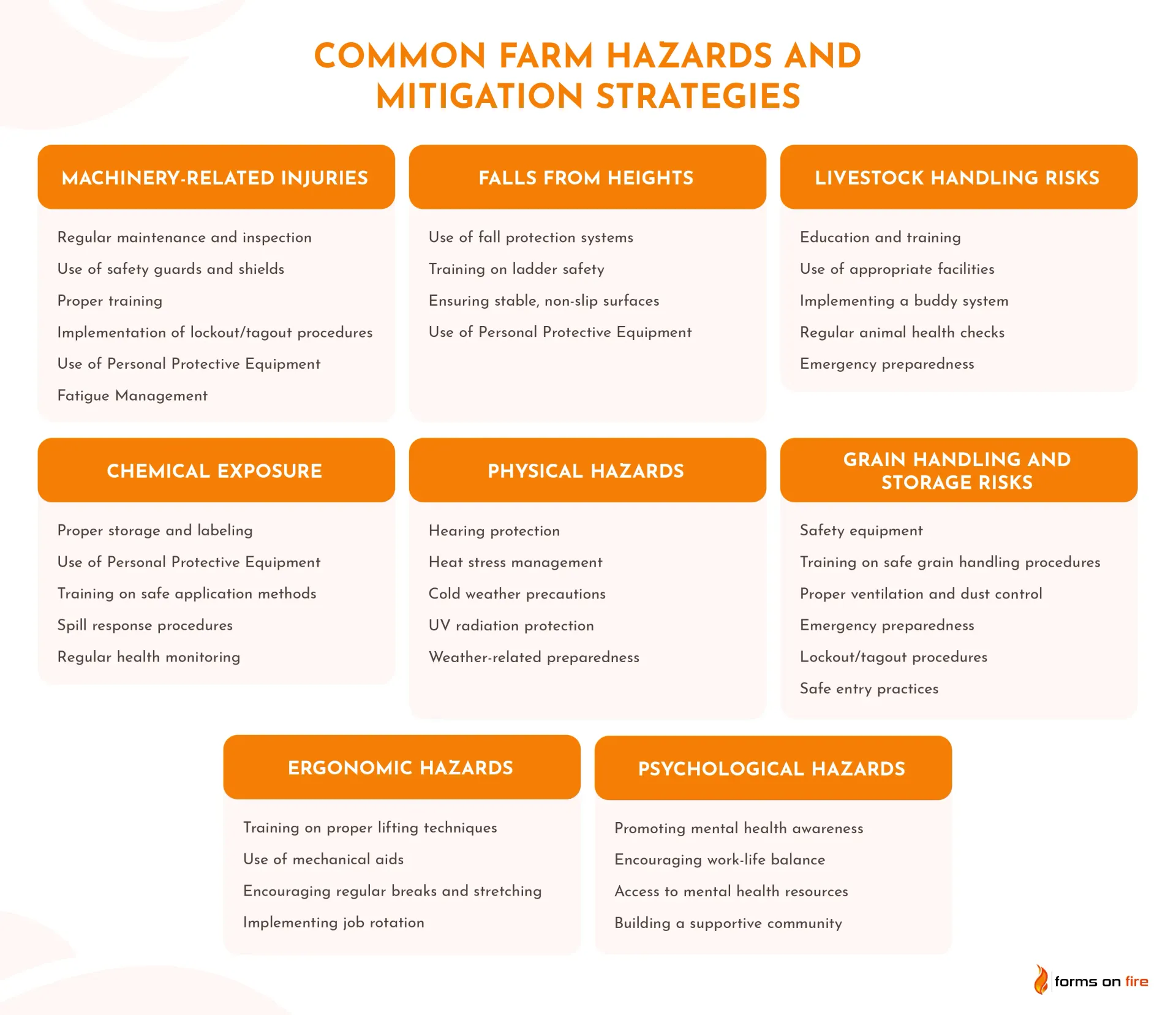

Addressing the eight most common farm hazards

The following list is in no particular order. There are two reasons why. First, we don’t have a reliable universal database of farm hazards across all states. And second — which kind of feeds into the first one — many farm safety incidents just never get reported.

How did we compile this list then? Well, we looked at the statistics we could find and double-checked that with our clients who work in the agricultural sector.

Without further ado, here are the most common farm hazards — with a list of potential mitigation strategies for each.

1. Machinery-related injuries

Injuries from machinery are among the most common and severe in the agricultural industry. They range from minor cuts and bruises to severe cases involving entanglement, crushing, amputation, and even death.

Tractors, combines, and other heavy equipment are particularly hazardous, especially when operated without proper safety measures. The risk is compounded by long hours of work, fatigue, and insufficient training, leading to accidents that could have been avoided.

Common mitigation strategies:

- Regular maintenance and inspection: Ensure all machinery is regularly inspected for wear and tear, with routine maintenance performed to keep farm equipment in optimal condition. Address any mechanical issues promptly to prevent accidents.

- Use of safety guards and shields: Equip all machinery with appropriate safety guards and shields, ensuring that they are never removed or bypassed. Regularly check that these guards are in place and functioning properly to protect operators.

- Proper training: Provide comprehensive training to all workers on the safe operation of farm machinery. This should include hands-on training for new operators and periodic refresher courses for experienced workers.

- Implementation of lockout/tagout procedures: Establish and enforce lockout/tagout procedures to ensure machinery is turned off and de-energized before maintenance or repair. Train workers on how to properly lock and tag equipment to prevent accidental startup.

- Use of Personal Protective Equipment: Require the use of PPE, such as gloves, steel-toed boots, and protective eyewear, when operating or working near machinery.

- Fatigue Management: Implement work-rest schedules to prevent fatigue, a common cause of machinery-related accidents. Encourage regular breaks and avoid working excessively long hours.

2. Falls from heights

It is estimated that falls from heights account for up to 30% of all farm safety incidents. Common scenarios where falls occur include working on ladders, silos, barn roofs, or elevated platforms. The danger is amplified by factors such as uneven surfaces, poor weather conditions, and the lack of proper fall protection gear.

Common mitigation strategies:

- Use of fall protection systems: Implement fall protection systems such as harnesses, guardrails, and safety nets when working at heights. And make sure workers know how to use this equipment.

- Training on ladder safety: Provide training on the correct use of ladders, including how to select the right ladder for the job, set it up securely, and maintain three points of contact while climbing.

- Ensuring stable, non-slip surfaces: Ensure that work surfaces at heights are stable and have non-slip coverings to reduce the risk of slipping or losing balance. In wet or icy conditions, take extra precautions to secure the area or delay work until it is safe.

- Use of Personal Protective Equipment (PPE): Require workers to wear appropriate PPE, such as non-slip boots and helmets, when working at heights.

3. Livestock handling risks

Simply put, animals are unpredictable. Injuries from livestock can range from bites and kicks to being crushed or trampled. The danger is particularly high during activities such as loading, unloading, herding, or medical treatment, where animals may feel stressed or threatened, leading to aggressive behavior.

Common mitigation strategies:

- Education and training: Educate workers on the behavior of the animals they handle, including signs of stress or aggression. Furthermore, training on safe handling techniques can significantly reduce the risk of injury.

- Use of appropriate facilities: Ensure that the farm is equipped with proper facilities for handling livestock, such as sturdy chutes, gates, and barriers. These structures help control the movement of animals and protect workers from direct contact, reducing the likelihood of injuries.

- Implementing a buddy system: Encourage the use of a buddy system when handling large or aggressive animals. Having another person present can assist in case of an emergency and help manage the animals more effectively.

- Regular animal health checks: Conduct regular health checks and vaccinations to maintain the well-being of the livestock. Healthy animals are less likely to exhibit aggressive behavior, which often stems from illness or discomfort.

- Emergency preparedness: Train workers on emergency procedures in case of an animal-related injury. This includes knowing how to safely retreat, seek help, and administer first aid if necessary.

4. Chemical exposure

Farms often use a variety of chemicals, including pesticides, herbicides, fertilizers, and cleaning agents, which can pose significant health risks if not handled properly.

Exposure to these chemicals can result in skin irritation, respiratory problems, or eye damage, as well as long-term effects including chronic illnesses or even cancer. The risk is particularly high during the mixing, application, and storage of these chemicals.

Common mitigation strategies:

- Proper storage and labeling: Store chemicals in a secure, well-ventilated area that is specifically designated for hazardous materials. Ensure all containers are clearly labeled with the contents and appropriate hazard warnings. Keep incompatible chemicals separated to prevent dangerous reactions.

- Use of PPE: Require the appropriate use of gloves, goggles, respirators, and protective clothing when handling or applying different chemicals.

- Training on safe application methods: Provide thorough training on the safe handling and application of chemicals. Workers should understand how to mix, apply, and dispose of chemicals safely.

- Spill response procedures: Establish clear procedures for responding to chemical spills, including the use of spill kits and PPE. Train workers on how to safely contain and clean up spills to prevent contamination and exposure.

- Regular health monitoring: Implement health monitoring programs for workers who are regularly exposed to chemicals. This can help in early detection of any adverse health effects and prompt intervention.

5. Physical hazards

Physical hazards on farms encompass a wide range of dangers, including excessive noise, extreme weather conditions, and prolonged exposure to ultraviolet (UV) radiation.

Noise-induced hearing loss is a common issue due to loud machinery such as tractors, chainsaws, and grain dryers. Farm workers are also no strangers to working in extreme heat and cold, which can lead to heat-related illnesses or hypothermia. Finally, prolonged exposure to the sun without adequate protection can result in sunburns and an increased risk of skin cancer.

Common mitigation strategies:

- Hearing protection: Encourage the use of earplugs or earmuffs when operating or working near loud machinery.

- Heat stress management: Provide ample access to water, ensure shaded rest areas, and schedule work during the cooler parts of the day. Educate workers on the signs of heat-related illnesses and the importance of staying hydrated.

- Cold weather precautions: During cold weather, provide appropriate clothing such as insulated jackets, gloves, and hats. Train workers to recognize the signs of hypothermia and frostbite.

- UV radiation protection: Promote the use of sunscreen with a high SPF, along with appropriate clothing.

- Weather-related preparedness: Develop plans for working in extreme weather conditions, including thunderstorms, high winds, and heavy rain. Ensure that workers are trained to recognize weather-related hazards and know when to stop work for safety reasons.

6. Grain handling and storage risks

Grain bins and silos can be particularly dangerous when proper safety measures are not in place.

Workers can be quickly engulfed by flowing grain, leading to suffocation, or trapped in confined spaces. Additionally, the buildup of grain dust, which is highly combustible, can lead to explosive incidents if ignited. The fine dust particles can also pose respiratory hazards, causing long-term lung damage if inhaled over time.

Common mitigation strategies:

- Safety equipment: Equip workers with safety harnesses, lifelines, and other fall protection equipment when entering grain bins or silos.

- Training on safe grain handling procedures: Provide comprehensive training on the dangers of grain handling and procedures for safely entering and exiting grain bins.

- Proper ventilation and dust control: Use dust collection systems and maintain proper ventilation in grain handling areas. Encourage the use of respiratory protection when working in dusty environments.

- Emergency preparedness: Develop and practice emergency response plans specific to grain handling incidents. This includes training workers on how to respond in the event of an engulfment, fire, or dust explosion, as well as ensuring that rescue equipment is readily available.

- Lockout/tagout procedures: Enforce strict lockout/tagout procedures for all machinery associated with grain handling, including augers and conveyors. This ensures that machinery is properly de-energized and cannot be accidentally started while workers are inside bins or near equipment.

- Safe entry practices: Implement a confined space entry program for grain bins, ensuring that all entries are authorized, supervised, and conducted with appropriate safety measures in place (i.e. follow a confined space entry checklist).

7. Ergonomic hazards

Farming often involves tasks like lifting heavy objects, sitting in a machine or bending over for extended periods, and performing repetitive tasks like milking or planting. These activities can lead to musculoskeletal disorders (MSDs), such as strains, sprains, back injuries, and repetitive stress injuries.

Common mitigation strategies:

- Training on proper lifting techniques: Educate workers on the correct techniques for lifting heavy objects to reduce the risk of back injuries. As the saying goes: Lift with your legs, not your back.

- Use of mechanical aids: Provide access to mechanical aids, such as dollies, hoists, or conveyors, to assist with moving heavy loads.

- Encouraging regular breaks and stretching: Promote regular breaks during repetitive or physically demanding tasks. Encourage workers to perform stretching exercises to relieve muscle tension and prevent injuries caused by repetitive movements or awkward postures.

- Implementing job rotation: Reduce the risk of repetitive strain injuries by implementing job rotation, where workers alternate between different tasks throughout the day. This prevents prolonged exposure to a single type of motion or posture.

8. Psychological hazards

Psychological hazards on farms often stem from high levels of stress, isolation, long working hours, and the unpredictability of farm life (financial instability, crop or livestock loss, weather challenges, etc.). These stressors can lead to mental health issues such as anxiety, depression, and burnout.

Common mitigation strategies:

- Promoting mental health awareness: Foster an environment where mental health is openly discussed and prioritized. Educate workers and farm managers about the signs and symptoms of mental health issues and the importance of addressing them early.

- Encouraging work-life balance: Promote a healthy work-life balance by encouraging workers to take regular breaks, time off, and to maintain a reasonable work schedule. Watch out for long hours and overtime to prevent burnout.

- Access to mental health resources: Offer access to mental health resources, such as counseling services, hotlines, and support groups. Make sure that workers know how to access these services and feel supported in doing so.

- Building a supportive community: Encourage social interaction and the building of a supportive community among workers. Regular team meetings, social events, and group activities can help reduce feelings of isolation and build a sense of belonging.

Other ways to reduce risks from farm hazards

Some of the research on farm accidents in the US suggests that up to 80% of farm accidents result from carelessness or failure to deal with hazards safely.

In other words, most farm safety accidents are avoidable. Here are two additional tips for proactive farm managers.

Perform a risk assessment and implement control measures

A safety risk assessment is a thorough process aimed at identifying, analyzing, and managing potential risks on a farm.

The process is fairly straightforward:

- Identify hazards on your farm

- Evaluate the risk level (likelihood and severity) for each identified hazard

- Prioritize risks to focus on

- Document the findings

- Implement risk control measures

For more details, we have a full guide on how to perform a farm health and safety risk assessment.

Follow general farm safety best practices

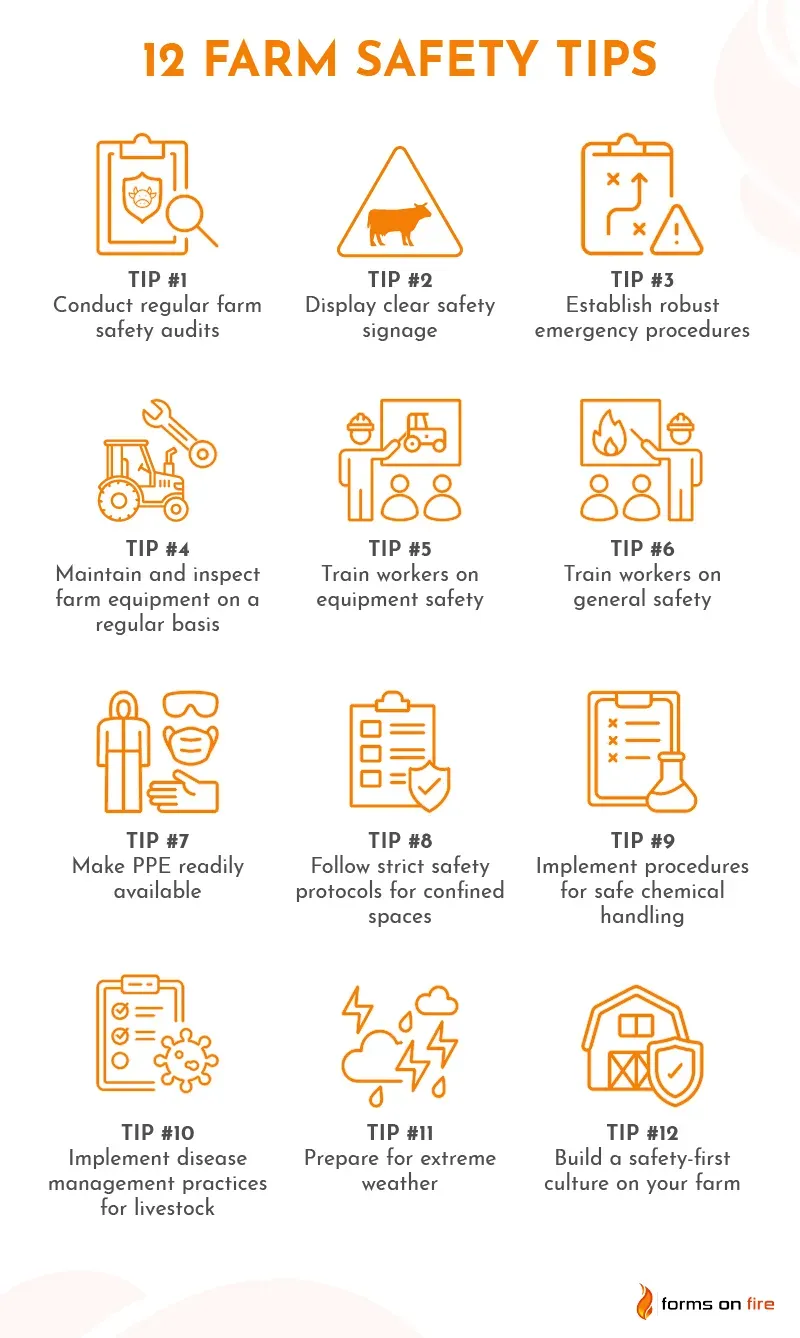

From displaying clear safety signage to building a safety-first culture, consider implementing one of the 12 general farm health and safety advice we discuss in the linked article.

How Forms On Fire makes farms a safer place

Forms On Fire is a no-code platform businesses from various industries use to build digital forms and apps.

In the context of improving safety, farmers and farm managers use it for:

- Custom safety checklists: Create tailored safety checklists and inspection forms to standardize various tasks and ensure people follow safety guidelines.

- Audits and assessments: Develop procedures for and conduct regular farm audits and risk assessments.

- Incident reporting: Enable quick and accurate reporting of incidents and hazards directly from mobile devices, with real-time data collection and analysis.

- Training and compliance: Build and manage training programs, track completion, and ensure all workers are up-to-date with safety protocols.

- Equipment maintenance: Schedule and log equipment maintenance to prevent machinery-related injuries, with automated reminders and detailed historical records.

- Emergency response plans: Develop and distribute digital emergency response plans, ensuring immediate access to critical information during emergencies.

You don’t have to stop here. You can build upon these forms, add new ones, and interconnect them — creating tailored farm management software for your needs.

We have a bunch of pre-made templates and amazing customer support that will get you up and running in no time.

Take our 14-day free trial or request a demo to get a personalized product walkthrough and see how Forms On Fire can improve safety and efficiency on your farm.