Optimizing Field Service Management: Tools and Best Practices

Managing a field service operation isn’t easy. Between juggling technician schedules, keeping track of equipment, and meeting rising customer expectations, there’s a lot that can go sideways. Paperwork gets lost, delays happen, inventory runs low — and it all adds up to frustrated teams and unhappy customers.

But it doesn’t have to be this way.

This article will walk you through the most effective ways to streamline field operations. We’ll cover what field service management involves, why it matters, and nine best practices to help your team work smarter, not harder.

We’ll also explore the tools companies use to digitize and automate their processes — including how no-code platforms like Forms On Fire can help you start small by building custom solutions.

Let’s start from the top.

What is field service management?

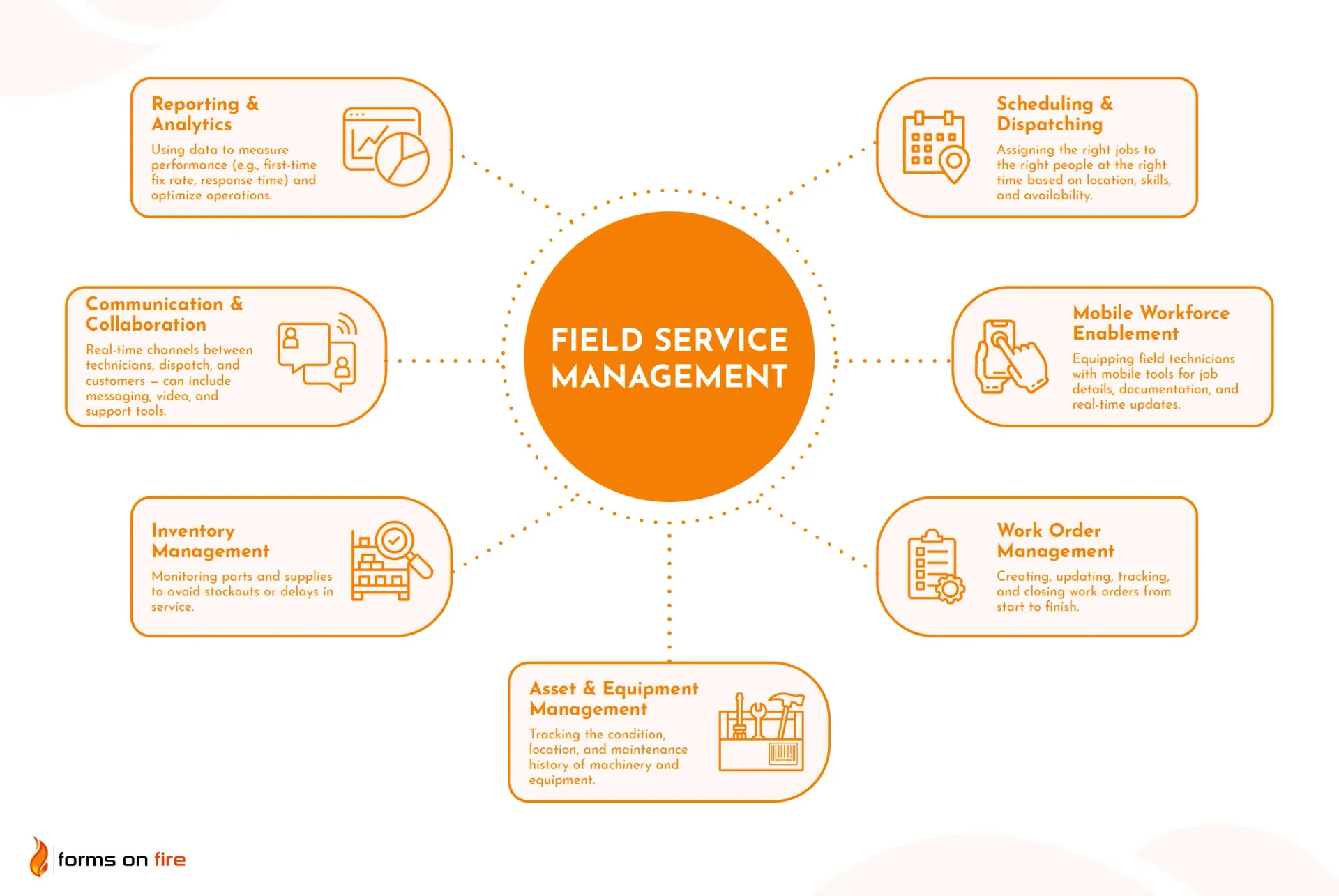

Field service management (FSM) is the coordination of field operations through a centralized system. It involves managing tasks like dispatching technicians, tracking job progress, maintaining equipment, handling inventory, and communicating with clients and customers — all in real time and often on the go.

The goal? To make sure the

right people, tools, and information are in the right place at

the right time.

Industries that rely heavily on field service management:

- Utilities: To schedule inspections, handle emergency repairs, and manage large teams of field technicians across broad service areas.

- Telecommunications: For installing and maintaining phone, internet, and cable infrastructure, often in remote or urban areas.

- HVAC and plumbing: For dispatching technicians, managing service calls, and keeping track of parts and service history.

- Construction: To coordinate equipment, labor, and materials across multiple job sites.

- Oil & gas: To track remote equipment, schedule maintenance, and ensure safety compliance in field operations.

- Transportation & logistics: For vehicle maintenance, route planning, and managing mobile teams and cargo.

When done right, field service management improves the productivity of your field teams and helps address some of the more common operational challenges. Customers get better services; businesses see better results — it’s a win-win scenario.

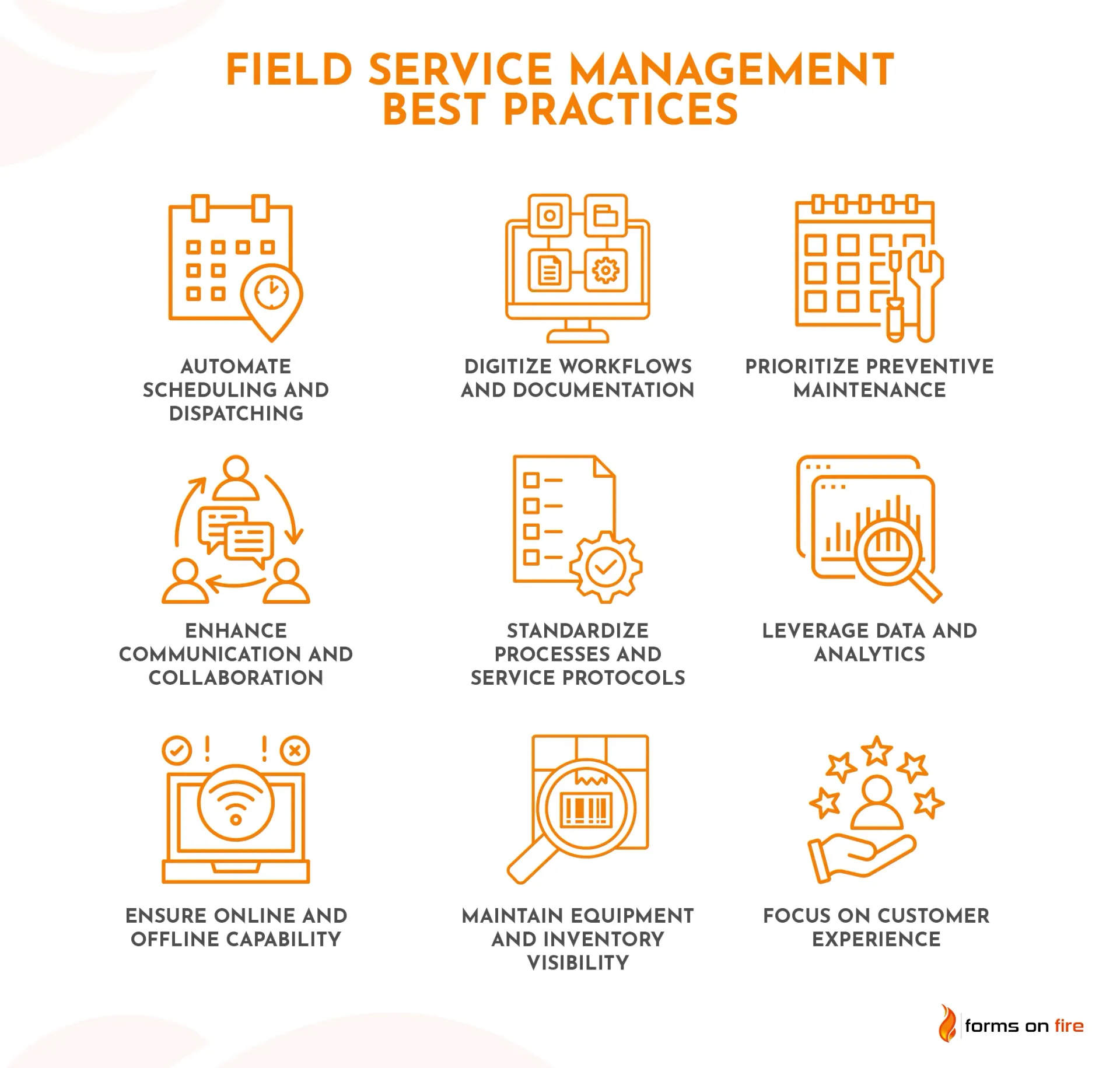

Top 9 field service management best practices

Running field operations efficiently requires smart systems, clear processes, and the right tools to stay ahead of the potential chaos. The following best practices are designed to help you do that — no matter the industry you're in.

1) Automate scheduling and dispatching

Manual scheduling is slow, error-prone, and hard to scale. Automating part of this process helps you assign the right technician to the right job faster — and with far less hassle.

- Use dynamic scheduling tools to match jobs with technicians based on real-time availability, proximity, and skill set. In most cases, you will still want a human to review and approve.

- Incorporate GPS tracking to optimize routes, reduce travel time, and improve response rates.

- Automate rescheduling and rerouting to handle last-minute changes like cancellations or delays to minimize disruptions.

With smarter dispatching, you’ll see fewer delays, happier customers, and a more efficient field team.

2) Digitize workflows and documentation

If your team still uses paper forms or spreadsheets, it’s time to upgrade. Switching to a digital workflow will not only save time but also reduce errors and make data instantly accessible.

Simple ways to do that include:

- Replace paper-based processes with mobile apps or digital forms. Customers should be able to report issues using a digital service request form. Field technicians should be able to complete checklists, capture photos, or collect signatures from a tablet or phone.

- Give technicians on-site access to manuals, customer history, job details, and service instructions in a digital form. Use tools that make it all accessible offline.

- Make sure your tools talk to each other. Your scheduling, inventory, customer data, and reporting systems should all sync seamlessly to avoid duplicate work or data silos.

Skilled technicians are hard to find these days. Their time should be spent doing the job, not chasing paperwork.

3) Prioritize preventive maintenance

If your company focuses on providing maintenance and repair services, waiting for things to break is a recipe for costly downtime and emergency callouts. Taking a more proactive approach to maintenance helps you stay ahead of problems — and saves money in the long run.

At minimum, you can be more diligent by performing routine inspections and setting scheduled service plans to catch wear and tear before it leads to failure.

If the situation and budget allow it, the ideal approach is to track asset lifecycle and usage data to determine optimal maintenance intervals. Smart sensors or IoT devices can help automate this.

4) Enhance communication and collaboration

Good communication is the glue that holds field operations together. Without it, jobs get missed, customers get frustrated, and your team wastes time chasing updates.

You can avoid those issues by:

- Enabling real-time communication between field teams and the back office with messaging apps or FSM platforms that support live updates.

- Keeping customers in the loop with status updates, technician ETAs, and job completion confirmations.

- Using chat, video calls, or AR support to assist technicians on-site with remote diagnostics or troubleshooting — especially useful for complex repairs or training newer team members.

Don’t gloss over communication problems — they’re often the root cause of delays and frustration. Whether it’s a missed update or a lack of clarity between the field and the office, minor miscommunications can waste a lot of time in the long run.

5) Standardize processes and service protocols

When every technician does things their own way, quality becomes inconsistent — and that’s a problem. Standardizing your processes helps ensure every job is done right, every time.

You can:

- Standardize service procedures across all teams so everyone follows the same steps, regardless of location or job type.

- Use digital checklists and templates to guide technicians through tasks, ensure compliance, and avoid missed steps.

- Run regular audits or spot checks to make sure standards are being followed and to identify areas for improvement.

Standardization doesn’t slow your team down — it gives them a clear, repeatable playbook so they can work faster and with confidence.

Sidenote: When standardizing work procedures and creating SOPs, include your most experienced technicians and supervisors in the process. Test them in the field and ask for feedback so you can polish the procedures before a company-wide rollout.

6) Leverage data and analytics

As organizations go digital, many field managers are buried in data — but not all of it is useful. The key isn’t collecting more; it’s knowing what to pay attention to.

When you focus on the right metrics, you can start answering questions like: Why are certain jobs taking longer? Which technicians consistently get it right the first time? Where are we losing time or money?

To optimize your field operations, consider the following:

- Monitor KPIs like first-time fix rate, response time, job completion time, and customer satisfaction scores.

- Analyze trends in technician performance, recurring customer issues, or equipment failures to fine-tune your operations.

- Use dashboards and reports to keep a pulse on your field performance and act on issues before they escalate.

If you are in a position where you do not have enough (timely) data, you most likely need new (or better) digital tools to work with.

7) Ensure online and offline capability

Not every job site has perfect signal — and if your tools rely on a constant internet connection, that’s a problem.

For starters, critical information like schematics, job instructions, and customer/service history must be accessible anytime. The work shouldn’t stop just because Wi-Fi does.

Ideally, you would equip technicians with mobile apps and forms that can work offline and automatically sync when a connection is available.

For example, with a platform like Forms On Fire, a technician can pull up a full service history before starting a job — even without internet access. They can then complete an inspection using a custom digital form, capture photos of any damage or wear, and collect a digital signature from the client on the spot. Once they’re back in range, everything automatically syncs to the cloud, updating the office and the customer record in real time.

8) Maintain equipment and inventory visibility

A technician shows up, but the part they need isn’t in the van — or worse, not even in stock. It’s a common problem, and one that slows everything down.

Avoid that by:

- Tracking inventory in real time to avoid shortages, overstocking, or wasted trips.

- Integrating your inventory system with procurement so that parts can be automatically reordered when stock runs low.

- Using barcodes or RFID tags makes it easier for technicians to scan and update inventory levels from the field.

- Standardizing the procedure for taking out and returning tools and items to inventory helps keep your stock up-to-date and track where your tools and equipment are.

There are hundreds of different inventory management tools out there. If you have trouble finding the right fit, you can always build a custom solution using Forms On Fire.

9) Focus on customer experience

Service companies that engage with customers need to nurture that relationship. It’s not just about fixing the problem — it’s about how the customer feels before, during, and after the service.

Here are a few tips that help create a smooth experience and build trust:

- Send appointment reminders and real-time updates so customers aren’t left wondering when someone will show up.

- Follow up after the job with a quick message or survey to gather feedback and show you care.

- Offer self-service options like portals or apps where customers can book appointments, check job status, or find answers to common questions.

- Train technicians on soft skills — a polite, well-informed tech can turn a routine service call into a 5-star review.

- Personalize the experience by using names, service history, and preferred communication methods (email, text, phone, etc.) to build stronger customer relationships.

Many of these things can be automated with the right tools. It's definitely worth the effort, as even small improvements in communication and convenience can leave a lasting impression.

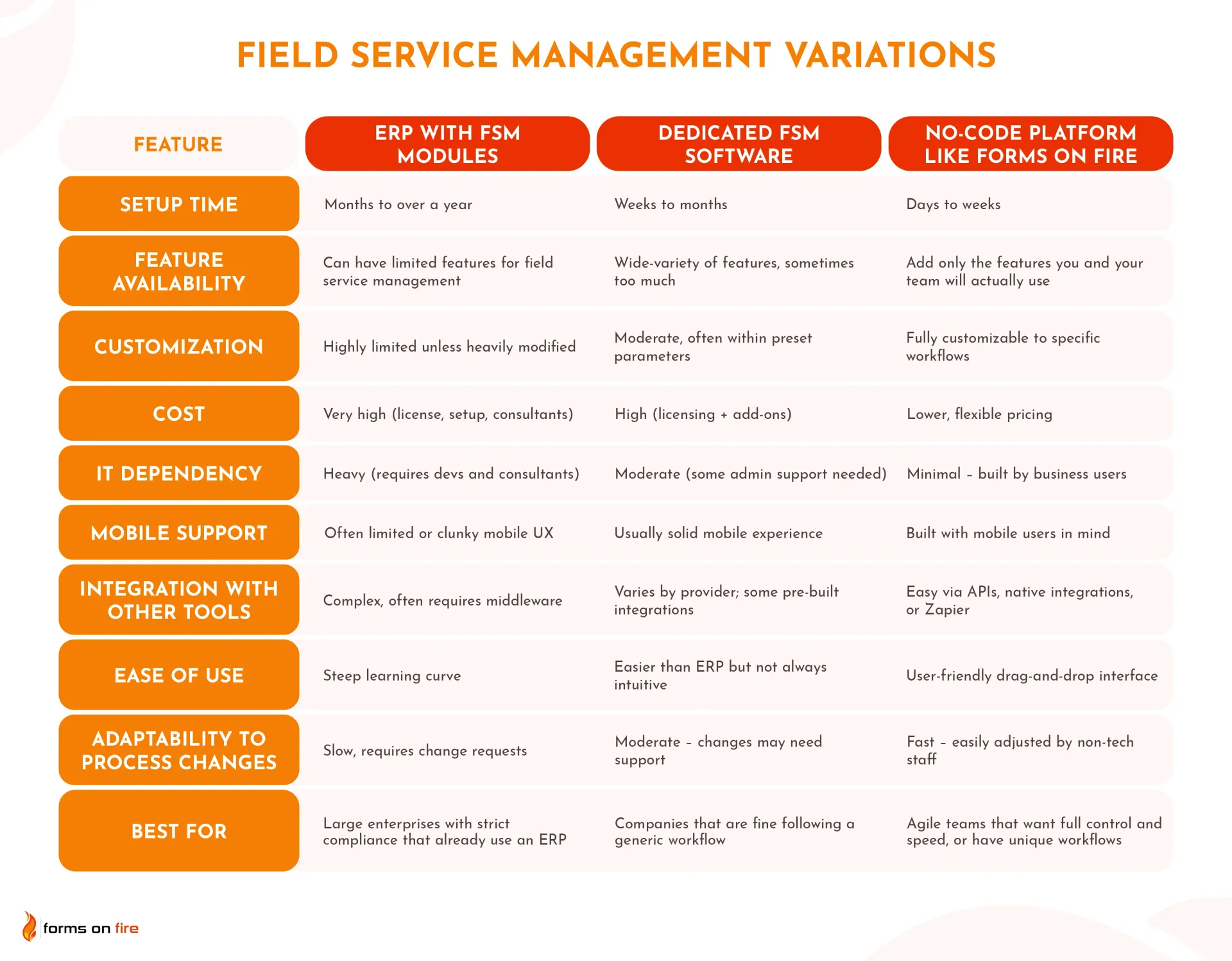

Tools for digitalizing your field operations

To run an efficient field service operation, going digital is no longer optional — it’s expected. Companies typically take one of two paths:

- Enterprise Resource Planning (ERP) systems with a built-in FSM module.

- Off-the-shelf field service management software designed specifically for scheduling, dispatch, and reporting.

These solutions work well for standardized operations, but they can be rigid, expensive to customize, and may require long implementation cycles.

An alternative? No-code platforms like Forms On Fire. You can use templates to quickly build your own field service workflows without writing code. Think: custom inspection checklists, job reports, digital forms, or field apps — all tailored to the way your team works.

Various software providers offer different features. If needed, you can complement your chosen solution with tools like:

- WhatsApp, Slack, Zoom, Google Meet, Microsoft Teams — for real-time team communication, video check-ins, training sessions, and remote troubleshooting.

- Google Maps, Waze, Circuit Route Planner, RoadWarrior for live traffic updates, multi-stop route planning and optimization.

- Various tools for inventory management and tracking.

- Make or Zapier to connect different tools and automate data flow between platforms.

- TeamViewer or AnyDesk — for remote equipment support or IT troubleshooting.

- TalentLMS or Trainual — for creating and sharing training modules or onboarding guides.

- Clockify, Toggl, QuickBooks Time — for tracking technician hours or billable time per job.

*There are many other viable solutions in each category; we just listed the more popular ones. Also, many of these tools' functionalities can be easily replicated using a capable mobile forms builder.

Use Forms On Fire as your field service management software

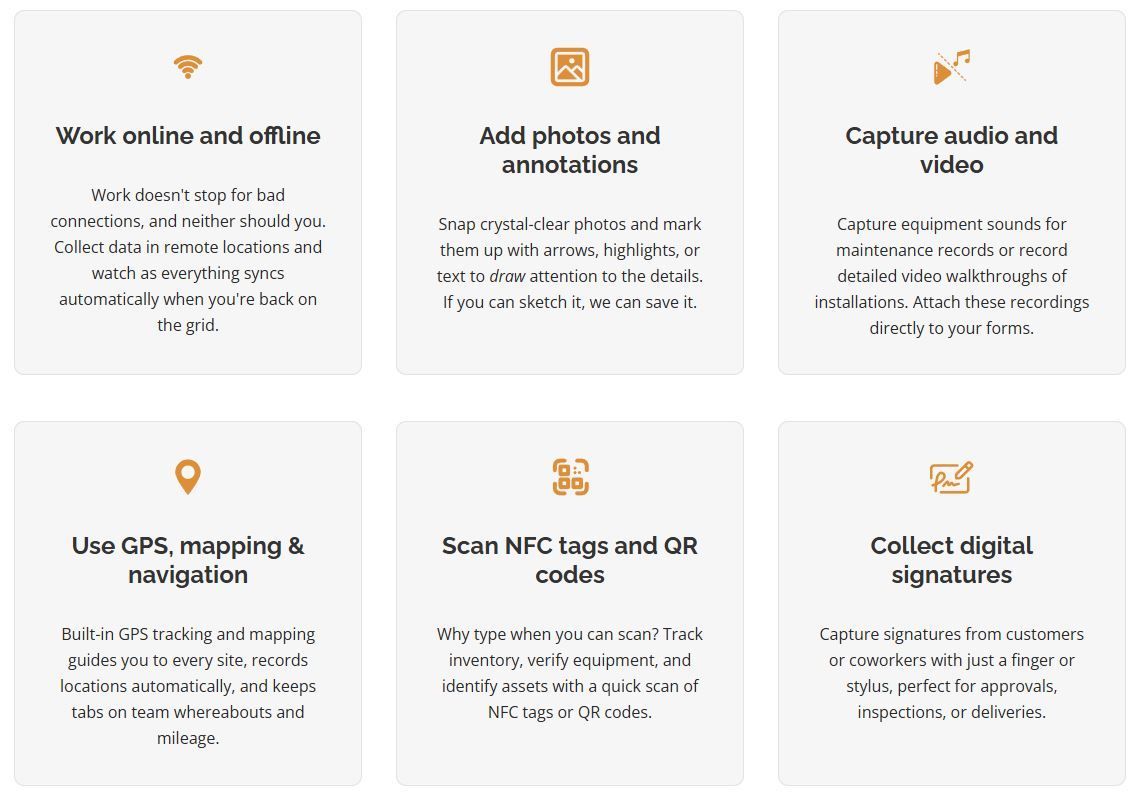

Forms On Fire is a no-code mobile platform that lets teams build custom forms, automate workflows, complete jobs in the field, collect data, and sync everything in real time. You don’t need to be a developer — just find a template in our database, edit it using drag and drop, and deploy it for your whole team to use.

We have a bunch of awesome, built-in features that help you fully customize your processes, especially if you manage frontline teams or have a mobile workforce.

And if you get stuck designing or deploying an app, our fantastic support team is always ready to jump in and help.

Case study: Alistair Group digitalizes logistics operations

Logistics company Alistair Group needed to improve data collection accuracy, reduce errors, and improve its maintenance operations. Using Forms On Fire, they replaced paper-based processes with multi-language forms for mobile inspections, digital safety checklists, instant alerts for mechanical issues, and real-time reporting. The result? Improved compliance, faster decision-making, and better visibility across the entire field operation.

Let us help you streamline your field operations by building smarter, more efficient workflows.

Schedule a demo — tell our team what you are trying ot accomplish and they will show you how Forms On Fire can help.