Ensure Compliance and Safety With Food Traceability Software

Every year, USDA orders somewhere between 40 and 130 food recalls. It is one of many regulatory bodies worldwide that have strict requirements to ensure food products can be traced throughout the supply chain.

A key role in that process is played by food traceability software. First, it protects consumers by minimizing health hazards from contaminated food. Secondly, it protects food producers by reducing economic losses from recalls.

Let’s see how food traceability works in practice and how to set up an effective food traceability system.

What is food traceability?

Food traceability refers to the ability to track the movement of food products and their ingredients throughout all stages of the supply chain — from production and processing to distribution and retail. Its primary goals are to ensure food safety, improve supply chain efficiency, enhance product quality, and facilitate compliance with regulatory standards.

Here’s the information that is commonly tracked:

- Origin details: Information about where the food product or its ingredients were grown, harvested, or produced. This includes farm identification, geographical location, and the producer's details.

- Batch numbers: Each batch of products is assigned a unique identifier, allowing for precise tracking. In case of a recall, specific batches can be easily identified and traced back through the supply chain.

- Production dates: The dates on which the food was harvested, processed, or packaged, helping to monitor shelf life and ensure freshness.

- Processing information: Details about the processing stages a product has undergone, including times, temperatures, and the types of processes applied (e.g., pasteurization, freezing).

- Ingredient details: Information about the ingredients used, especially in processed foods, including the source and batch of each component.

- Shipping and handling data: Records of how the product was handled and transported, including storage temperatures, transportation methods, and timelines.

- Expiration dates: The expiry or best before dates, which are crucial for managing the sale and safe consumption of food products.

- Compliance data: Documentation that the product meets relevant safety and quality standards, including certifications and inspection results.

- Destination details: Information about where the product is distributed, including the final retailer or the end consumer in the case of direct deliveries.

Who is responsible for food traceability?

Responsibility for food traceability lies with all participants in the food supply chain, from producers and manufacturers to distributors, retailers, and even food service providers. Each entity must maintain accurate records and ensure the traceability of food products as they move through the supply chain.

In the US, The Food and Drug Administration (FDA) oversees food traceability under the Food Safety Modernization Act (FSMA). The FSMA requires companies in the food supply chain to maintain records that will help the FDA quickly identify and address sources of foodborne illness.

FDA has a detailed food traceability list with specific foods that require additional recordkeeping capabilities due to their risk profiles. It covers perishable goods such as meats, dairy products, seafood, and fresh produce.

The exact tracking requirements will also depend on your location and market. For instance, The Canadian Food Inspection Agency (CFIA) has specific traceability regulations, as does the EU as a part of their General Food Law.

Internal vs external traceability

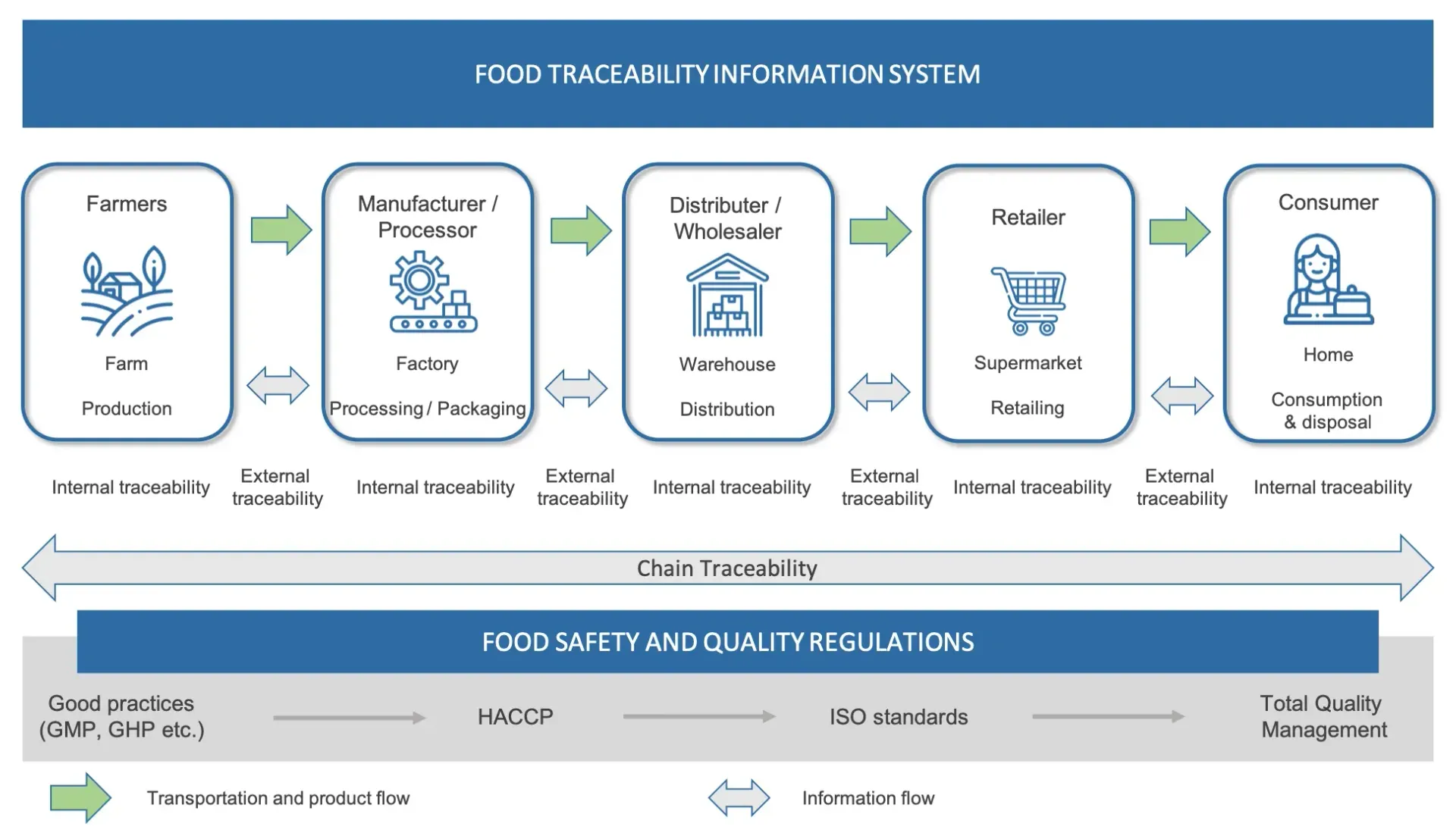

Effective traceability in the food supply chain can be categorized into two main types: internal and external traceability.

Internal traceability refers to the tracking of food products within a single organization. This involves monitoring every step of the product’s journey through the internal processes of a company, from receiving raw materials to processing and packaging.

Internal traceability systems help ensure that each batch can be traced back to its source, and forward through every stage of handling and transformation within the company.

External traceability focuses on the movement of food products between different entities in the supply chain. For effective external traceability, data like the unique product identification number and batch/lot number must be communicated clearly to all participants along the distribution channel. These identifiers must be included on product labels and correlated with the relevant paper or electronic business documents.

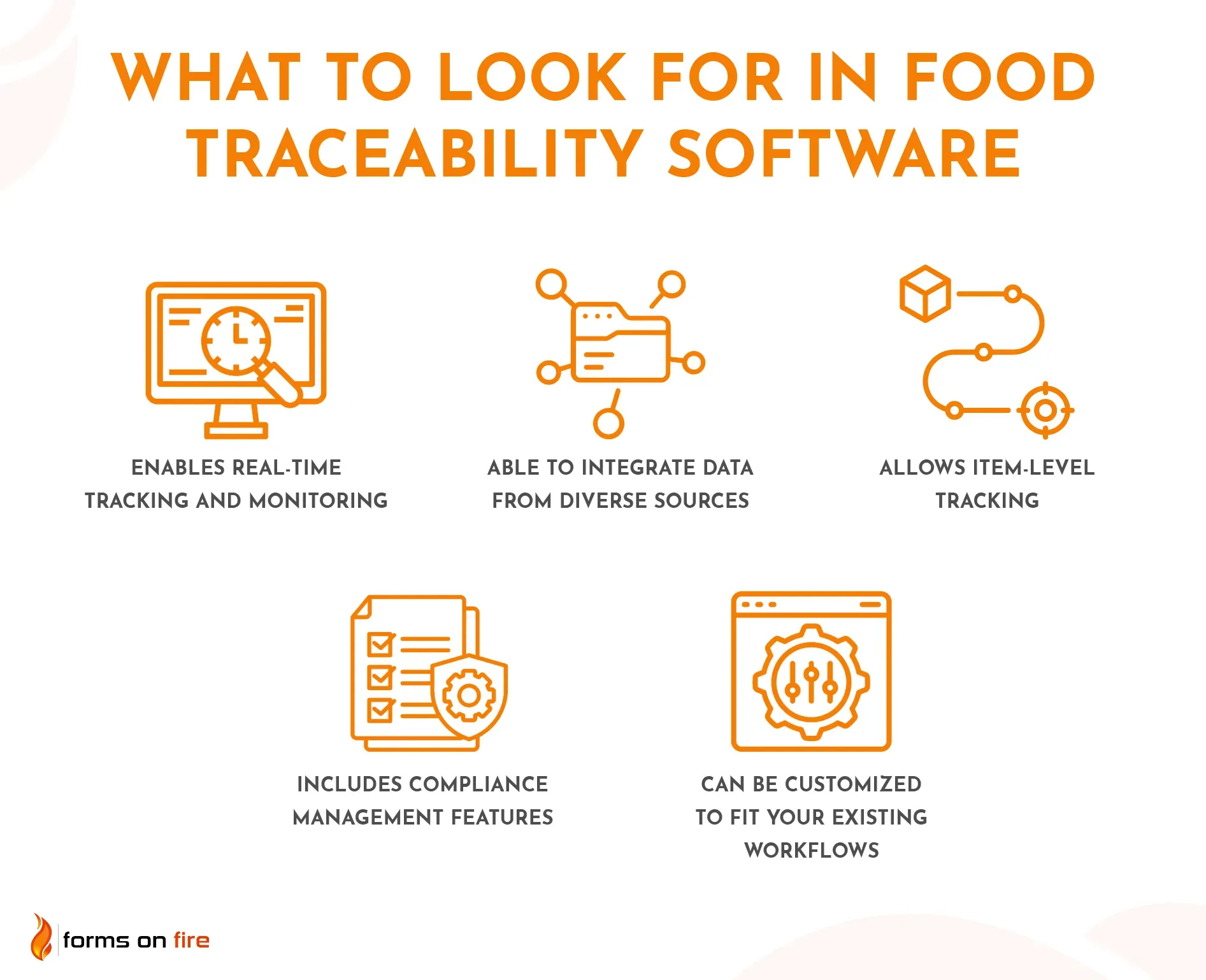

What to look for in food traceability software

Considering the complexity behind food traceability, digital solutions are indispensable. Food traceability software is used to collect, manage, and analyze data to ensure the origin, path, and handling of food items are accurately documented.

Let’s see what a proper food traceability system should be able to do.

Enables real-time tracking and monitoring

Real-time tracking provides immediate visibility into the status and location of food products. Businesses can monitor conditions such as temperature and humidity, which are crucial for perishable items. By ensuring optimal conditions during storage and transport, you can significantly reduce spoilage and loss.

Able to integrate data from diverse sources

Effective food traceability software must be capable of integrating data from a wide array of sources. It’s the key to creating a seamless and comprehensive view of the supply chain.

Look for solutions that offer:

- Centralized data management: Integrating diverse data sources into a centralized system simplifies monitoring and analysis. This could include data from farmers, processors, distributors, and retailers, encompassing everything from production details to shipping logs and sale records.

- Cross-functional accessibility: Different departments within a company — such as logistics, quality control, and sales — should be able to access the same information in real time.

- Enhanced analytical insights: The software should enable you to use existing data to identify trends, forecast demands, and optimize processes.

- Adaptability to regulatory changes: As regulations evolve, having a system that can integrate new types of data or adapt to new data standards is crucial. This is where custom-built solutions have a big advantage.

Allows item-level tracking

Item-level tracking enables businesses to monitor individual items or batches throughout the supply chain. It can be immensely helpful for quickly identifying and isolating issues without needing to compromise larger quantities of stock.

To simplify item-level tracking and improve its accuracy, your food traceability software should be able to integrate and communicate with technologies like GPS, RFID tags, and barcodes.

Includes compliance management features

Based on local and international standards, every food business will have a set of information they need to track — so they can share it with their partners in the supply chain or provide it to regulatory bodies upon request.

Any digital system you use for food traceability purposes should allow you to track, store, and share all of the required data with ease. This means being able to:

- Manage all compliance-related documents such as certificates of analysis, safety data sheets, and audit records.

- Generate comprehensive traceability reports, automatically or on demand.

- Provide quick access to all necessary documentation and data to demonstrate compliance during inspections.

Can be customized to fit your existing workflows

An effective food traceability software is one that seamlessly integrates into your existing workflow. Oftentimes, the only way to achieve that is to build a system using a custom app builder like Forms On Fire.

You can decide exactly which information you need to track and how, you can set unique processing rules, and you create highly customizable reports and dashboards. Furthermore, you can integrate your freshly built solution with existing IT infrastructure, such as ERP, warehouse/inventory management, and logistics systems.

Companies avoid this approach because it seems complex. In reality, most custom app builders offer a bunch of pre-made forms and automations you can quickly adjust to your needs.

Build your own food traceability system with Forms On Fire

At its core, food traceability is not that complicated — you need to track specific data points and have a way to quickly and easily share that information with partners and regulatory bodies.

The only way to do that accurately over a long period is to digitize data collection. This means replacing manual data entry and paper forms with mobile forms that automatically save data to a central database.

Forms On Fire is perfect for that. You can create custom digital forms and integrate them with virtually any existing software you might be using. Workers can even use them to collect data offline, so you don’t have to worry if you operate in areas with poor internet connectivity.

You can go a step further and build a whole system that tracks RFID, barcode, and GPS data, generates automatic reports, and sends automatic alerts to teams based on IOT sensor data.

Schedule a quick demo to get a personalized product walkthrough and see how you can leverage the Forms On Fire platform to comply with all food traceability standards.

FAQ about food traceability

What is the FDA food traceability rule?

The FDA Food Traceability Rule, part of the Food Safety Modernization Act (FSMA), requires specific foods deemed at higher risk for causing foodborne illnesses to have detailed tracking records. This rule aims to enhance the FDA's ability to quickly trace, track, and respond to food safety issues with foods like certain cheeses, seafood, and leafy greens, thereby improving outbreak response and preventing foodborne illnesses.

The outlined rules on the link above are going to be enforced from January 20, 2026.

What is the difference between recall and traceability?

A recall is an action taken to remove a product from the market due to safety concerns or regulatory non-compliance, often triggered by the discovery of contamination, mislabeling, or safety defects.

Traceability, on the other hand, refers to the ability to track the history, location, or application of a product through recorded identification. It plays a crucial role in facilitating efficient recalls by pinpointing where and how a problem occurred in the supply chain.

What is traceability in the food supply chain?

Common technologies used in food traceability systems include barcodes and QR codes for easy product identification and scanning; RFID for wireless tracking of goods; GPS for monitoring transportation routes; and IoT (Internet of Things) devices for real-time data collection about product conditions.

These technologies work together to ensure accurate and efficient tracking of food products throughout the supply chain.

Company

Contact

Platform

Resources

Use Cases

Industries