How to Audit Inventory: Checklist, Procedures, and Best Practices

Regular inventory audits are crucial for any business that manages stock — they help you catch discrepancies early, prevent stockouts, maintain accurate financial records, and optimize your overall operations.

But let's be honest: traditional audit methods can be time-consuming, prone to errors, and sometimes feel like searching for a needle in a haystack of SKUs.

The good news? A well-planned, systematic approach to inventory auditing can transform this necessary task from a dreaded chore into a quick and relatively painless process.

This guide walks you through building an audit system that works for you, from choosing the right counting methods to leveraging modern tools — all designed to deliver reliable results without disrupting your operations.

Inventory audit basics

Think of an inventory audit as your organization's vital health check — it systematically checks if your physical stock matches what your records show. Your goal is to detect inefficiencies, identify discrepancies, and maintain tight control over one of your most valuable assets before they can hurt your bottom line.

For businesses in retail, manufacturing, wholesale, or eCommerce, accurate inventory data is paramount. When your daily decisions and financial planning rely on precise stock information, regular inventory audits become a fundamental business practice, not an option.

While your team can handle day-to-day inventory counts, formal audits need an independent eye. Think of it like proofreading — it's always harder to catch your own mistakes. You might use internal auditors who know your business but don't manage inventory directly, or bring in external experts for a completely fresh perspective.

Public companies don't get a choice here though — they must use external CPAs to meet regulatory requirements under AICPA Auditing Standards and ensure complete objectivity.

Common inventory counting methods you can choose from

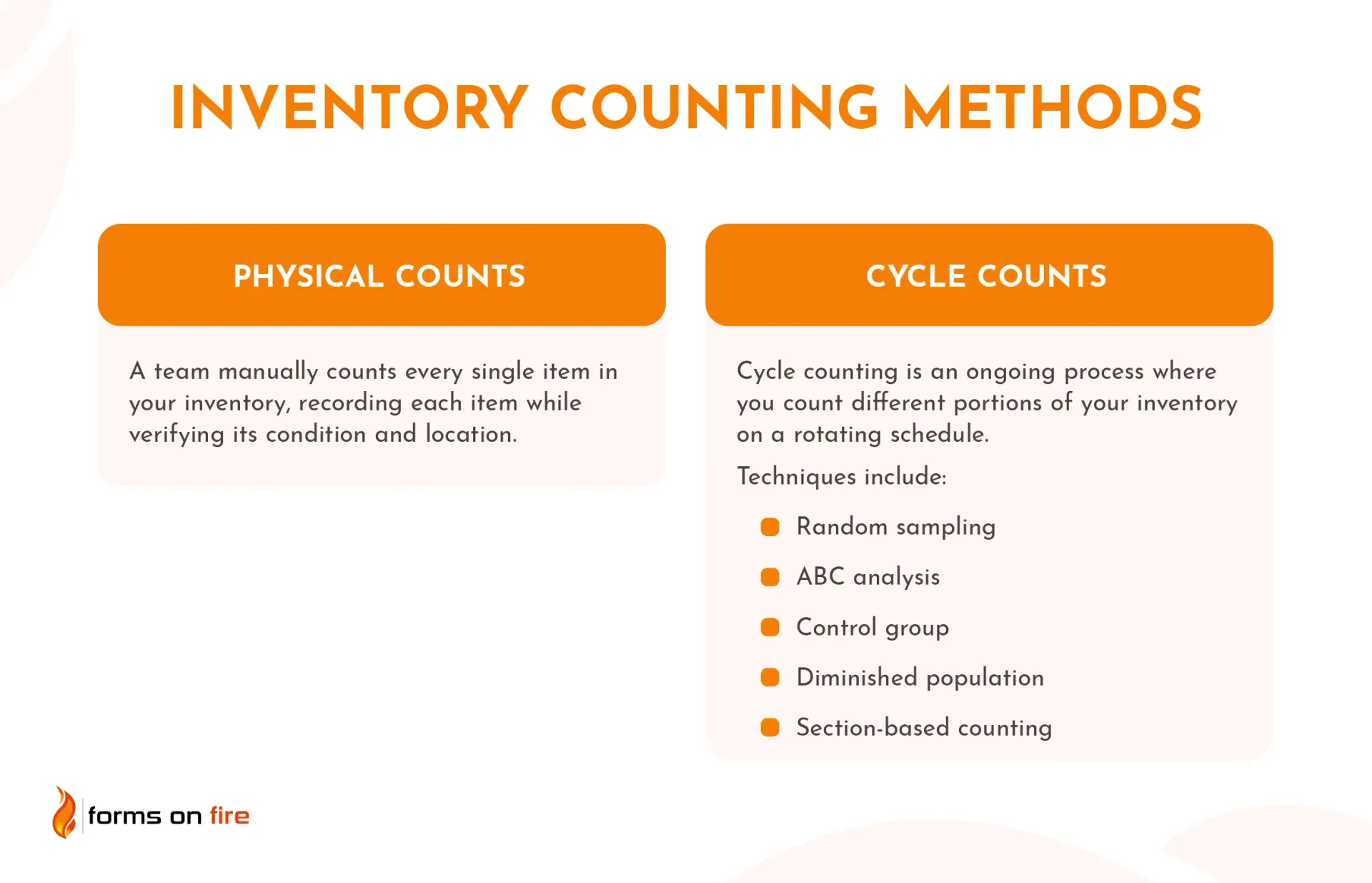

Let's explore the two main approaches — physical counts and cycle counting — and see how each one might work in your location.

Physical counts

A physical count is exactly what it sounds like — your team manually counts every single item in your inventory. During this process, teams systematically work through your warehouse or storage areas, counting and recording each item while verifying its condition and location.

By counting everything at once, you get a complete picture of your inventory position. However, this thoroughness comes with a trade-off — you'll typically need to pause regular operations during the count to ensure accuracy.

This is where cut-off analysis is useful. It is an audit procedure where you ensure that no inventory is received or removed from the warehouse during the audit. In other words, it helps you determine exactly which inventory should be included in your count:

- Which outbound shipments to include?

- Which incoming deliveries do you count?

- How do you handle orders picked but not shipped?

- What to do with received items not yet processed?

These decisions impact accuracy and your ability to reconcile the results with your financial records.

Cycle counts

Unlike full physical counts that happen once or twice a year, cycle counting is an ongoing process where you count different portions of your inventory on a rotating schedule. This helps you spot and address discrepancies faster while keeping your operations running smoothly.

Here are five different ways in which you can execute cycle counts:

- Random sampling: You select and count a different set of items each day. For instance, if you find discrepancies in 10 out of 50 randomly counted items, you know it's time to investigate your overall inventory accuracy.

- ABC analysis: Your most valuable items (A) get counted most often, while less critical items (B and C) need less attention. An electronics store might count laptops weekly, accessories monthly, and basic cables quarterly — putting their effort where the value is.

- Control group: This method uses a carefully selected group of items to monitor your inventory system's health. A clothing retailer might pick 20 representative products – from bestselling jeans to seasonal jackets — and count them regularly to catch any inventory issues early.

- Diminished population: Count a portion of items each day, mark them as done, and move on to uncounted items. A warehouse might verify 100 items each Monday until they've covered everything, then start fresh.

- Section-based counting: Break your warehouse into manageable sections and count one area at a time. For instance, if a distribution center keeps different types of inventory in different sections of the warehouse, they can count electronics on Monday, sporting goods on Tuesday, etc.

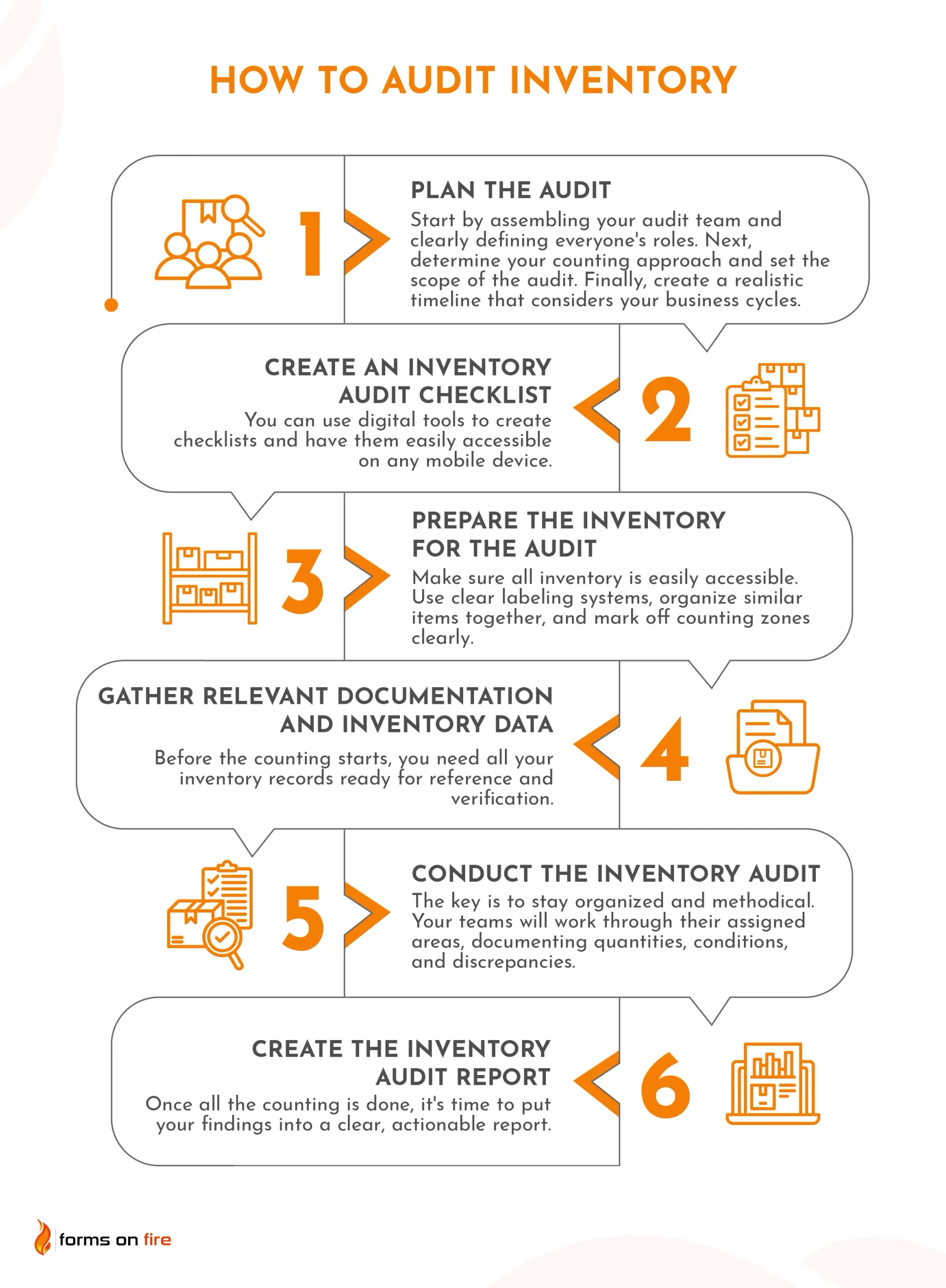

The typical inventory audit process

To ensure accuracy and efficiency, a successful inventory audit needs to follow a logical sequence of actions. From planning to reporting, each step builds on the previous one to create a comprehensive view of your inventory.

1. Plan out the audit

If you are doing an internal inventory audit, start by assembling your audit team and clearly defining everyone's roles. You'll need:

- Counters who know your products well

- Supervisors to oversee the process

- A “reconciliation specialist” to handle any discrepancies.

Each team member should understand exactly what they're responsible for and how their part fits into the bigger picture.

Next, determine your counting approach. Will you conduct a full physical count, or does a cycle counting method make more sense for your operation? Consider your business needs — a retail store might choose section-based counting during off-hours, while a large warehouse might opt for ABC analysis to focus on high-value items first.

Set clear boundaries for your audit scope. If you're not doing a full count, decide which inventory segments you'll examine. Maybe you're focusing on your fastest-moving items, or perhaps you're auditing seasonal merchandise before peak periods. Be specific about what you're counting to keep the process manageable.

Finally, create a realistic timeline that considers your business cycles. Choose counting periods when stock levels are naturally lower and team members are most available. Factor in time for preparation, counting, and addressing any discrepancies you discover.

2. Create an inventory audit checklist

A good inventory audit checklist does more than just track tasks — it helps your whole team stay on the same page and ensures nothing falls through the cracks. Today, you can use digital tools to create checklists and have them easily accessible on any mobile device.

While every business can have its own approach, there are typical steps most organizations will want to do in different phases of the inventory audit process.

Below are quick, simplified examples.

Pre-audit preparation checklist:

- Verify all recent transactions are properly recorded.

- Ensure receiving and shipping are paused during counting.

- Check that all inventory locations are clearly marked.

- Confirm counting equipment is calibrated and ready.

During the audit:

- Document item locations and quantities.

- Note any damaged or obsolete inventory.

- Track lot numbers and expiration dates.

- Record any discrepancies for investigation.

Post-audit activities:

- Reconcile physical counts with system records.

- Investigate and document count variances.

- Update inventory management system as needed.

- Prepare final audit report with findings.

A structured approach helps everyone know exactly what needs to happen. Plus, it makes training new team members and maintaining consistency across different audit sessions much easier.

3. Prepare the inventory for the audit

Start with the basics: make sure all inventory is easily accessible: unpack incoming shipments and ensure pallets can be reached from all sides. Confirm that no items are hidden away where they might be missed or counted twice. Organize similar items together — when auditors can count uniform groups instead of individual pieces, you'll save hours of counting time.

For example, consider an auto parts manufacturer preparing for their audit. They might organize all brake pad components by model type on dedicated shelves, with raw materials in one section and finished products in another.

By storing 200 sets of the same brake pad model on each pallet and marking work-in-progress items, they turn a complex counting job into a straightforward process. Instead of counting individual components across different production stages, auditors can quickly verify complete pallets and clearly separated production batches.

Smart organization makes a huge difference too. Use clear labeling systems and make sure your warehouse layout matches your management system.

Other than that, try to:

- Separate different product categories clearly

- Create uniform counting units where possible

- Keep aisles clear and well-lit

- Label storage areas clearly

- Ensure all recent receipts are processed

- Mark off counting zones clearly

You can also map out your warehouse and organize products by category (such as shelf or pallet) using inventory and warehouse management software. When auditors can pull up exact item locations and quantity expectations on their devices, they spend less time searching and more time counting.

4. Gather relevant documentation and inventory data

Before the counting starts, you need all your inventory records ready for reference and verification. This step is crucial when working with third-party auditors who need a complete picture of your inventory management.

Ideally, here's what you should have ready:

- Previous inventory reports and adjustments

- Recent purchase orders and receiving documents

- Current sales orders and shipping records

- Stock movement and transfer records

- Inventory valuation reports

- Details of any damaged or obsolete stock

- Return and warranty claim records

Having these documents easily accessible helps auditors understand your inventory flow and verify any discrepancies they might find during the count. It also speeds up the reconciliation process once the physical count is complete.

5. Conduct the inventory audit

Now comes the main event — the actual counting process. Whether you're doing a full physical inventory or cycle counting, the key is to stay organized and methodical. Your prepared teams will work through their assigned areas, documenting quantities, conditions, and discrepancies.

Here are some proven tips to keep your audit running smoothly and accurately:

- Use two-person counting teams — one to count, one to record. This simple buddy system significantly reduces errors.

- Count from left to right, top to bottom in each zone. Having a consistent pattern helps ensure nothing gets missed.

- Mark counted items or zones clearly to avoid double-counting. A simple colored sticker or tag can prevent major headaches.

- Document discrepancies immediately when you find them. Don't wait until the end of the day when details might be fuzzy.

- Take photos of unusual situations or discrepancies. They'll help during reconciliation and future planning.

- Keep communication channels open between counting teams and supervisors for quick problem-solving.

- Take regular breaks to maintain counting accuracy. Tired teams make more mistakes.

- Verify high-value items twice. The extra time spent is worth it for your most important inventory.

- Hold off on receiving and shipping during the count if possible. If you can't, carefully document any movement.

6. Create the inventory audit report

Once all the counting is done, it's time to put your findings into a clear, actionable report. The report should include:

- Summary of findings and key discrepancies

- Detailed count results compared to system records

- Value of adjustments needed

- Identified patterns or problem areas

- Root causes of significant variances (if identified)

- Recommendations for improvement

- Accuracy rates by product category or location

- Documentation of any unusual findings

The only thing left is to use these insights to improve your operations. Look for patterns in your findings:

- Are certain products consistently showing discrepancies?

- Do specific locations have higher error rates?

- How do these results compare to previous audits?

- Which inventory items might need more frequent counting?

- What process improvements could prevent future variances?

Based on these answers, you might decide to adjust your cycle counting frequency for certain items, improve storage methods for problem areas, or update handling procedures where most errors occur. Remember, a good audit report doesn't just tell you what's wrong — it helps you make things right.

Other inventory audit procedures you can include in the audit process

While the main audit steps form your foundation, several supporting procedures can make your audit more thorough and insightful. Here's how each one adds value to your process:

- Barcode labeling: Speed up counting and reduce errors by ensuring every item has a scannable barcode. Modern scanning systems can instantly record product details, location, and quantity, making your audit faster and more accurate.

- Inventory reconciliation: Compare your physical count results with your system records to identify and investigate any discrepancies. This process helps you understand where your inventory tracking might be falling short and what needs fixing.

- Matching invoices to shipping logs: Verify that your shipping records match your sales invoices and inventory movements. This cross-check helps catch any documentation gaps that might be causing inventory discrepancies.

- Inventory KPI analysis: Track key financial and operational metrics like turnover rates, holding costs, and accuracy rates to spot trends and potential issues. These numbers tell you not just what's happening with your inventory, but why it's happening.

- Checking inventory levels: Whether you're using FIFO (First-In-First-Out), LIFO (Last-In-First-Out), or weighted average cost, this check helps you maintain optimal stock levels while ensuring your accounting practices align with your chosen inventory management strategy.

Speed up inventory auditing with Forms On Fire

Forms On Fire is a no-code platform you can use to build simple digital forms or custom apps. For example, you can build a digital checklist for your teams to follow during the audit process — or a whole inventory app that tracks the location and status of your inventory.

Either way, our mobile-first solution will help you transform traditional paper-based counting into streamlined digital workflows that reduce errors and save time.

With Forms On Fire, you can:

- Create custom digital audit forms that match your exact process

- Enable real-time data collection during counts

- Create audit checklists to standardize the whole process

- Access inventory records instantly from your mobile device

- Generate automated audit reports

- Track audit progress in real-time

Stop wrestling with paper forms and manual data entry. Let’s help you build a more efficient, accurate inventory audit process that scales with your business.

Reach out to our team or book a demo to learn more.

FAQ about inventory audits

How often should an inventory audit be performed?

The frequency of inventory audits depends on your business type and volume. While most businesses conduct full physical counts annually, many supplement this with regular cycle counts throughout the year. High-volume retailers might perform cycle counts weekly or monthly, while smaller operations might stick to quarterly checks.

What is the role of an inventory auditor?

An inventory auditor verifies the accuracy of your inventory records by comparing physical stock against system data. They're responsible for conducting counts, documenting discrepancies, investigating variances, and recommending process improvements.

What are the four categories of inventory?

Inventory typically falls into four main categories:

- Raw materials: components used in manufacturing.

- Work-in-progress: partially completed products.

- Finished goods: ready-to-sell products.

- MRO supplies: maintenance, repair, and operating materials used to keep your business running.

How hard is it to audit inventory?

While inventory audits require careful attention to detail and good organization, they don't have to be overwhelming. The key to success lies in proper planning, clear procedures, and the right tools for your operation. With a systematic approach and appropriate technology support, even large-scale audits can be managed efficiently.