How to Solve the 6 Biggest Operational Challenges

Operational challenges are obstacles or issues within a company's day-to-day processes that slow productivity, waste resources, or create bottlenecks. Left unresolved, these challenges can lead to all kinds of inefficiency, ultimately hurting your bottom line.

Achieving operational excellence — streamlined, efficient, and effective operations — is essential for long-term growth and competitiveness. Companies that prioritize solving operational issues are better equipped to adapt, innovate, and maintain high customer and employee satisfaction.

With that in mind, let’s see how to identify, navigate, and overcome the six most common operational challenges companies face today.

Solving the most common operational challenges

Every organization faces operational hurdles, but some challenges consistently show up across industries and business types. Below, we'll tackle six of the most common operational issues faced by businesses that manage frontline and/or mobile workforce.

1) Inefficient workflows and processes

Inefficient workflows — whether they're outdated, overly complex, manual, or poorly documented — slow down productivity, lead to more errors, and reduce a company's agility.

Often, these inefficiencies persist because they're hidden, employees resist change, or companies don't actively work on improving internal processes. When left unchecked, they can become deeply embedded, hurting both productivity and morale.

Potential solutions:

- Audit your current workflows: Regularly reviewing and mapping processes will quickly highlight bottlenecks, redundancies, and outdated practices. It is an integral part of Business Process Optimization.

- Simplify and automate: Eliminate unnecessary steps and find ways to automate repetitive tasks. If you work at a large organization, look into enterprise workflow automation.

- Encourage employee involvement: Supervisors and employees who perform daily tasks should know what's inefficient. Invite their feedback, encourage suggestions, and empower them to propose solutions.

- Standardize work: Leverage your most experienced and skilled workers to identify best practices and create Standard Operating Procedures for recurring tasks. Documenting standardized workflows makes processes easier to follow, train, and consistently improve.

Fixing inefficient workflows makes everyone's job easier. It frees up time and energy, so your team can focus on the quality of their work.

2) Talent acquisition and retention

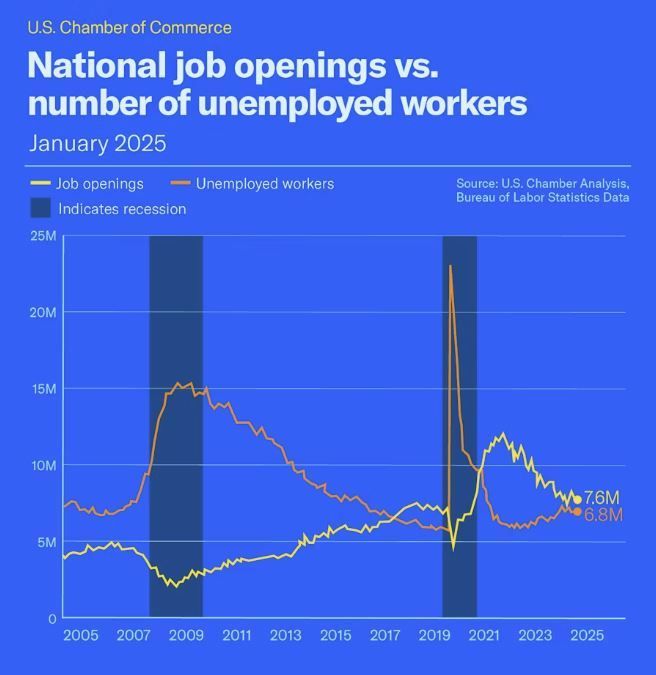

Finding and keeping great employees is tougher than ever. Many companies struggle to recruit and retain skilled talent

because of labor shortages and shifting workplace expectations. The statistics show that

even if we had zero unemployed workers in the US, around a million jobs would still be open.

If you're constantly battling turnover or feeling the pinch of unfilled positions, it can disrupt your entire operation — leading to stressed teams, decreased productivity, and unhappy customers.

Potential solutions:

- Strengthen your employer brand: Show why your company is a great place to work. Highlight your culture, values, perks, flexibility, and opportunities for growth. The truth quickly comes out, so make sure your promotional statements reflect reality.

- Offer competitive compensation and benefits: Regularly benchmark salaries and benefits against industry standards. Employees are more likely to stay if they feel fairly compensated for their contributions.

- Prioritize employee engagement: Provide meaningful work, recognition, clear career paths, and opportunities for professional development. Employees who feel valued and involved are more likely to stay loyal.

- Cross-train your workforce: Cross-training helps you do more with what you have. For example, manufacturing companies can train machine operators to perform basic servicing tasks (like lubrication or cleaning) so their maintenance team can focus on more complex work that requires specialized knowledge.

- Adapt to changing preferences: Where feasible, embrace flexibility like remote or hybrid work options to attract a broader range of talent and increase employee satisfaction.

It is difficult to create a frictionless workplace for the frontline teams. You don’t have to strive for perfection, but you should at least try to be better than your competitors.

3) Digital transformation and technology integration

New technology promises huge improvements, but implementing it successfully can be tricky.

Companies often struggle to integrate modern tools into their outdated legacy systems or overcome resistance from employees uncomfortable with change. Plus, with higher dependence on technology, there are increased cybersecurity risks.

When technology integration stalls or fails, productivity drops, frustration grows, and you lose potential competitive advantages.

Potential solutions:

- Develop a clear roadmap: Outline exactly what technology you'll adopt, why it's necessary, and how you'll implement it step-by-step. Transparency reduces uncertainty and encourages buy-in.

- Focus on integration: Choose technologies that integrate smoothly with your existing systems. Prioritize flexible, user-friendly solutions that minimize disruption.

- Invest in employee training: Offer clear, hands-on training and continuous support. Employees who feel confident using new tech will adopt it faster, with less resistance and fewer user mistakes.

- Strengthen cybersecurity: Regularly update security protocols and train your team to follow basic best practices. Proactively addressing security concerns makes everyone feel safer adopting new technologies.

Approach digital transformation as an ongoing journey rather than a one-time event. You can’t build an agile, secure, and tech-savvy organization overnight.

4) Managing complexity and scale

As your company grows, so do the complexities you must manage — more moving parts, stakeholders, and layers in your supply chain. Small issues can quickly snowball into big disruptions.

Without clear systems for handling complexity, your operations can become fragile, leading to delays and increased operational costs.

Potential solutions:

- Standardize, simplify, and digitize processes: Digitize paper forms and develop straightforward, repeatable systems that scale easily. Consistent processes reduce complexity and prevent confusion as you grow.

- Leverage technology to improve visibility: Use tools such as ERP (Enterprise Resource Planning) systems, dashboards, and analytics software to quickly identify problems, track performance, and manage resources more effectively.

- Establish clear communication: Ensure your teams know exactly who's responsible for what, how to report issues, and how decisions are made. Transparent communication makes complexity easier to handle.

- Build flexibility into your operations: Create contingency plans and adaptable processes. When disruptions occur, you will be able to respond swiftly without compromising overall stability.

It is impossible to avoid all growing pains. However, optimizing processes and planning ahead will make scaling your operations less stressful.

5) Cost management and profitability

Controlling costs while maintaining quality is a tough balancing act. Inflation, rising raw material costs, labor expenses, and overhead can quickly eat into your profit margins.

If you're too aggressive with cost-cutting, product or service quality might suffer, damaging your reputation and customer satisfaction. But if you ignore rising costs altogether, your profitability and competitiveness take a hit.

Potential solutions:

- Monitor your expenses closely: Regularly analyze spending to catch unnecessary costs early. Use budgeting and forecasting tools to anticipate and prepare for fluctuations.

- Negotiate better terms: Work closely with suppliers to negotiate more favorable contracts, discounts, or flexible payment terms, especially for long-term or bulk purchases.

- Optimize operations: Look for efficiency improvements — reduce waste, automate repetitive tasks, and streamline processes wherever possible. Efficient operations naturally reduce costs without compromising quality.

- Evaluate pricing strategy: Review your pricing models regularly. Depending on market conditions, you may need to adjust prices strategically to protect margins while remaining competitive.

Keeping a close eye on costs and actively managing profitability ensures your business remains financially healthy and competitive, no matter the economic climate.

6) Regulatory compliance, safety, and sustainability

Keeping up with regulations isn't optional — and it's getting harder. With constantly changing laws around data privacy, environmental protection, workplace safety, and corporate responsibility, staying compliant can feel overwhelming.

Ignoring or underestimating these regulations can lead to costly fines, damaged reputation, or even legal trouble.

Potential solutions:

- Stay informed and proactive: Regularly monitor regulatory changes affecting your industry. Stay ahead by designating someone internally (or partner externally) to manage compliance.

- Embed safety and compliance into your culture: Thoroughly train your team on compliance and safety protocols, and try to make compliance training fun to improve retention. Encourage employees to speak up if they see potential issues, creating shared responsibility for safety and compliance.

- Digitize compliance: Use digital solutions to simplify inspections and audits, manage documentation, and ensure nothing slips through the cracks.

- Improve sustainability: Where it makes sense, adopt environmentally friendly practices and transparent governance. Sustainability isn't just good for compliance — it's increasingly important to customers, employees, and investors.

Be sure to set your priorities straight. Being 10% more environmentally friendly is great, but almost nobody will care about that if you file dozens of safety incident reports each month.

Start solving your operational issues today

Don’t wait until your operational challenges become crises. Instead, proactively address these issues before they escalate.

Start by conducting internal audits to identify inefficiencies. Involve employees directly in process improvements, invest in technologies that streamline workforce management, and enhance communication and employee training programs.

Remember, operational excellence isn’t accidental — it’s the result of strategic planning, flexible technology, continuous improvement, and being open to adapting as you go.

Want to boost productivity, profitability, and employee satisfaction and gain a competitive edge? Then, you will have to tackle these operational challenges head-on!

Start by employing digital solutions like Forms On Fire to automate workflows, streamline data collection, and make life much easier for your team. Learn more by

contacting our team or

scheduling a quick product demo.